Thanksgiving with my family and a few doctors visits. Just part of the schedule when trying to get time to work on the boat. All of those events took me away from Reedville for several days. Driving to and from Washington, D.C. can be tiresome. And I will be going back in a few days for some minor out-patient surgery.

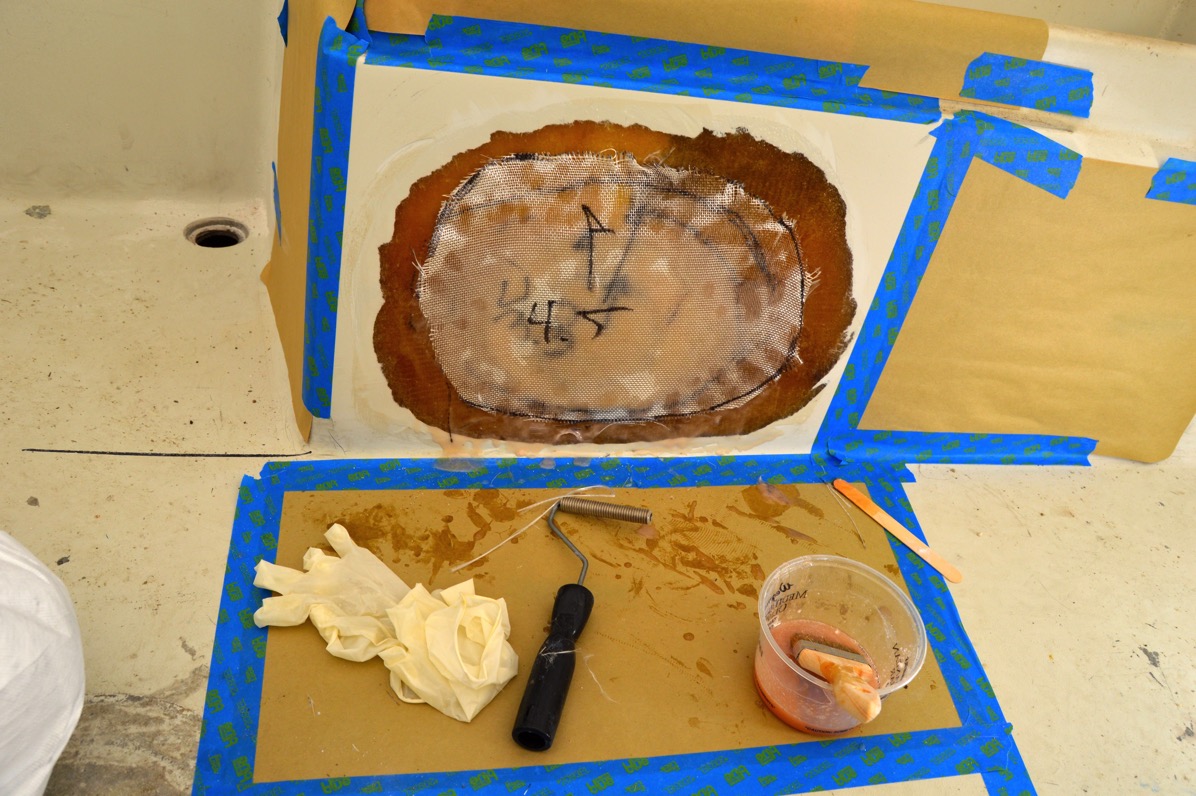

In-between the interruptions I continued work on filling in the old round port providing ventilation to the quarter berth. I cut up some layers of 17 oz. biaxial cloth to fit the diameter of the opening and epoxied them in place. From there I used the plastic template I had created some days earlier to cut up successive layers of 6 oz. woven cloth. These were epoxied into place until the entire area was built up.

Plug it and cover it.

Yes, still more wetting out to be done...

Pro tip: don’t use paper or tape for the epoxy overrun. The epoxy just ignores it and sets up on the glass anyway. And I knew that prior to taping it up. Dummy at work yet again...

I put a heat lamp on the whole thing and let it set up for the day.

The next day I came back and started in on sanding the hardened epoxy. After a quick wash to remove the amine blush I did a a couple of passes with the 5” grinder and the 6” sander. Despite my weak fiberglassing skills the layup was nice and fair with virtually no high spots that needed working down.

Ready for AwlFair.

I grabbed the vacuum to remove any dust and then washed the entire area with acetone. After mixing up a batch of AwlFair and troweling it on, I was done with that for the day.

I love AwlFair...

I took a quick trip to the bow and sanded the last AwlFair application near the forward part of the anchor locker and it is ready for priming when that occurs next Spring.

Done enough.

When I came back next I discovered the limitations of PeelPly. I had considered just using plastic between the wood backing plate and the epoxy buildup. I should have.

The wooden plug was firmly fixed in place. If it had been in a more accessible location it would have been fairly easy to remove. It was not.

So, breaking out the “Wonder Tool", my Fein Multimaster I was able to cut and pry the plug out in small bits. Ultimately it was notas onerous a task as I had envisioned.

Bits and pieces.

And since I had it ready I changed the blade and chopped off the wooden dowels I used to plug the old winch holes on the cabin top near the cockpit when filling them with epoxy.

Eh, no one will see it.

After some sanding with the 6” Mirka DA and some of board filing I applied another skim coat of AwlFair.

Break out the heat lamp again.

No comments:

Post a Comment