I think that at this moment it would be important for me to put down some thoughts about this effort that are not necessarily focused on what techniques, tools and processes that are being used to repaint Ronin. I know that I spend an inordinate amount of time scanning the internet for sources of techniques and tools required to complete the tasks and projects of this refit.

After observing how Charlie is approaching this project, I think some observations are in order.

First, he is doing this project from front to back. From arranging the haul dates with me, the length of time expected to complete the hull, the scope of work, the pros and cons of tackling certain aspects of the project to blocking the hull, prepping and painting the boat. There are no other people involved. Just Charlie.

I feel as though I have relinquished control my boat and, to some degree, the vision for how it will turn out to him. But here’s the thing, after seeing several of his other jobs and working with him, I can’t imagine any other way to see it through. Although I think that I have a basic level of understanding about how to accomplish this job and a level of understanding about a good job versus a perfect job, it is clear to me that that the final outcome is going to be a level of detail that's a good cut above.

I’ve seen other Awlgrip paint jobs that are good. The hull is sanded, gross imperfections or defects repaired, prior paint jobs sanded off and then the hull repainted. That is not what is going to happen. As I watch Charlie work on the boat I can see that he is repairing gelcoat and laminate problems which is all well and good. But when I watch him sand, prime, sand and prime again to a level of fairness that 95% of owners would not even be aware of and then exceed that level, I am am impressed. It isn’t a matter of discussion with us as to whether this is needed or not. For Charlie it will be perfect and nothing less is acceptable.

When I was planning on painting the boat myself, my expectations of the final results were much, much lower. I would have been fine with that. I don’t have the chops to do more. My results would have passed the 15 yard distance away level of beauty, no sweat.

It has become clear to me that when this job is done, the hull will be more fair than when it left the factory. The finish of the paint will be of Hinckley quality.

Now, does it make sense to do that to a 33-year old production sailboat? No. Will others even notice or care? Probably not. Will we get the expense back on resale? Not a chance.

But will I appreciate the level of effort? Yes. I’m certain that every time I row away from the boat and look back at her I will be reminded of the dedication to the highest level perfection.

Sanding, priming, sanding, priming...

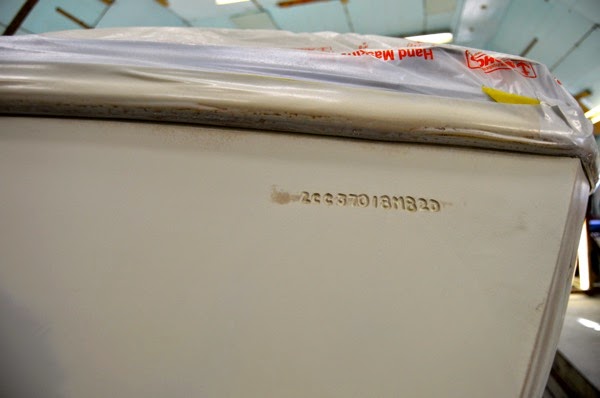

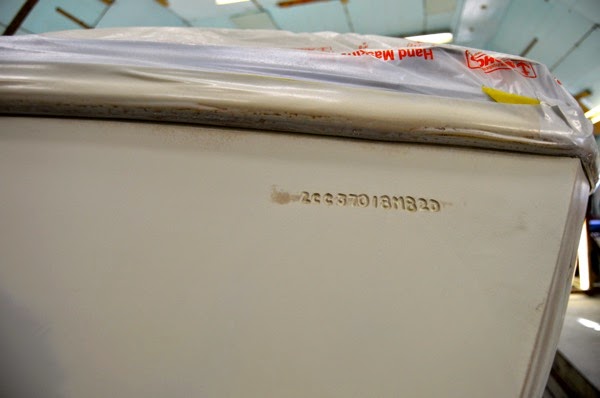

I was concerned that already faint HIN numbers would get lost in the final outcome. Charlie’s fix was to take a Dremel tool and open them up:

While the boat work has been proceeding in the boat shed, I have (very…) casually been working on the new cabin sole flooring.

First cut:

When I replaced the floor years back I converted the design from three access hatches to just two that were a bit longer. That proved to be a minor irritation because I couldn’t really get to the back part of the bilge for cleaning and finding lost tools.

For this iteration, I will go back to three access hatches.

Laying out the hatch boards:

Expanding the opening with a 10 inch cut:

This last weekend we lost power for almost 24 hours due to high winds from a brutal front passing through. Since the house was cold and we couldn’t get our daily internet fix, we jumped in the truck and drove to our favorite oyster and beer spot, Merrior in Topping, VA. One of the sights that is always sobering to me when we arrive is below.

Sad old derelict at very low tide:

As the story is told, apparently a gentleman brought her in to escape the ravages of Hurricane Isabel (2003) but she went down anyway. And the owner passed away a few days later...