There are times when it becomes pretty clear to me that although I may think that I have a pretty good hand working on boats it really isn’t true. Today I made a costly mistake. Something that was so stupid and silly that I realized that I was hacking away at this refit. A truly boneheaded mistake.

The weather for the past two days has been rain. Lot’s of it. At least three inches and it’s raining still as I write this. But I’ve been pretty psyched because I’ve been able to get back to the refit due to the protection provided by the new shed. I can tell that it is going to help speed the work schedule.

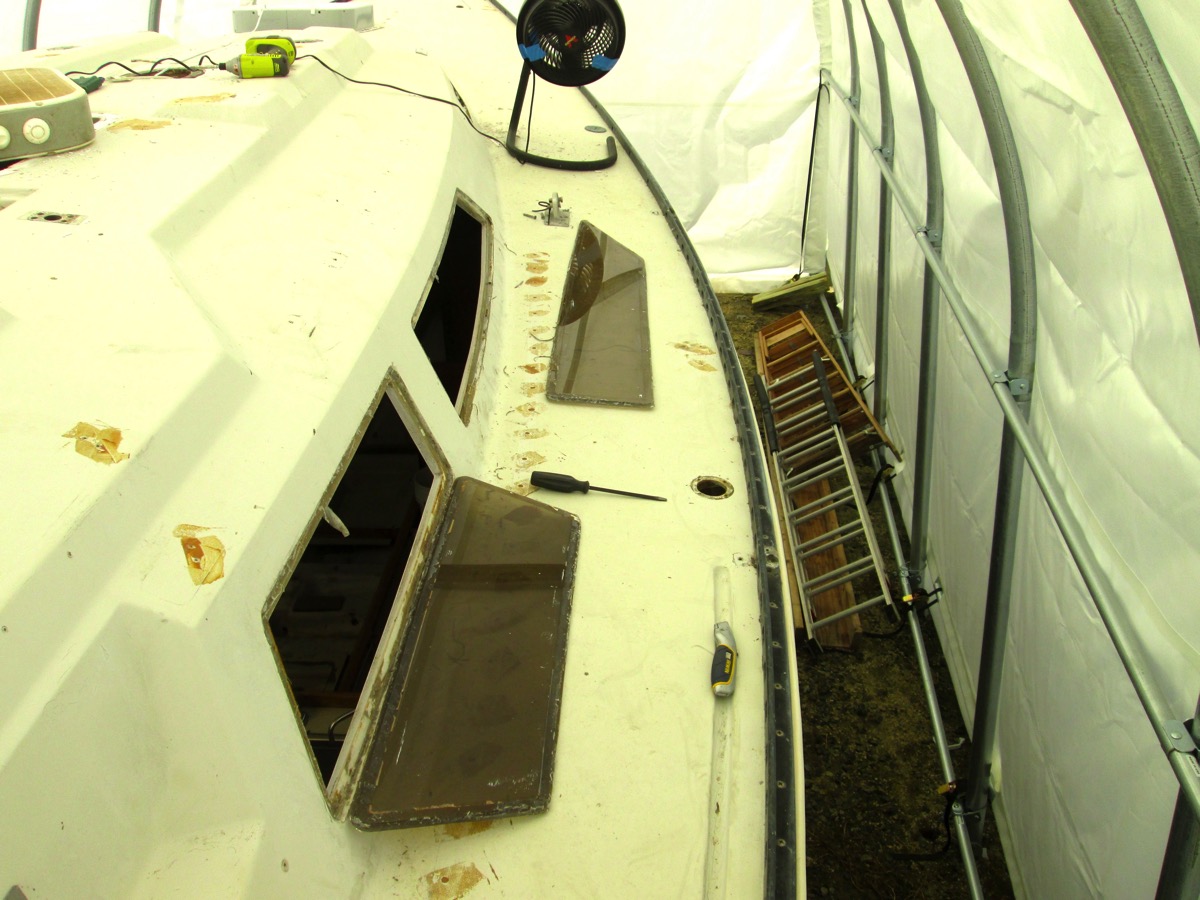

So, there I am, finishing off the removal of the last of the deck hardware items that had to stay put until the boat was under cover. Some water and holding tank deck fills, the dorades and the two hatches. The front hatch came off easily. Disturbingly so. Although it it’s been some time since the boat was subjected to heavy seas I’m pretty sure that it would have developed a leak. I had the hatches rebuilt sixteen years ago and re-bedded them myself. I made a mental note to do a better job next time using butyl as a sealant.

The main cabin hatch did not want to come free so easily. I slowly but steadily worked a gasket scraper between the frame and the deck, cutting the sealant. After some time working my way around the frame I could see that it was starting to free up. So, I started to pry the frame up. It was tougher than I thought. And not paying attention, I was also bending the frame...

As soon as I removed it from the deck I realized what I had done. I clamped the hatch shut and sure enough, a gap large enough to allow gallons of water to rain down on the interior. One heavy duty Atkins & Hoyle hatch ruined.

Anyway, despite the expensive setback given that I will almost certainly need to purchase a new hatch, probably a Lewmar of some sort and do some glass-work to get it to fit, I kept working on prepping the hull for work. One step forward, two steps back.

Hardware removal wreckage:

As part of the cleaning process prior to upgrading the interior I had to clean out the space behind the chainplates. The factory had apparently drilled the bolt holes and bolted the chainplates up pretty quickly. In the tight spaces behind there was a great deal of sawdust and fiberglass shards. Along with that were some nuts and washers that must have fallen off during the install which they just left behind.

Extra hardware:

I disconnected the fresh water tank plumbing and pulled the tanks out for storage. One of the interesting things about the tanks and lines on this boat has been the fact that there has been no mold or gunk. Frankly, the potable water on Ronin has always been pretty good. I hope to keep it that way.

Tanks gone:

Next to go were the fresh-water fill hoses, manual and automatic bilge pump lines and the mast baseplate.

Still a mess:

Well, I can tell myself that I’m maximizing my time by being able to work on the boat when ordinarily conditions would prohibit it. Not a great deal of consolation given the cost of replacing the main hatch...

Forty Days and Forty Nights….