Still working on the new and upgraded bilge pump systems. After measuring and climbing underneath the cockpit a week ago I started to finalize my thoughts about how to go about the project.

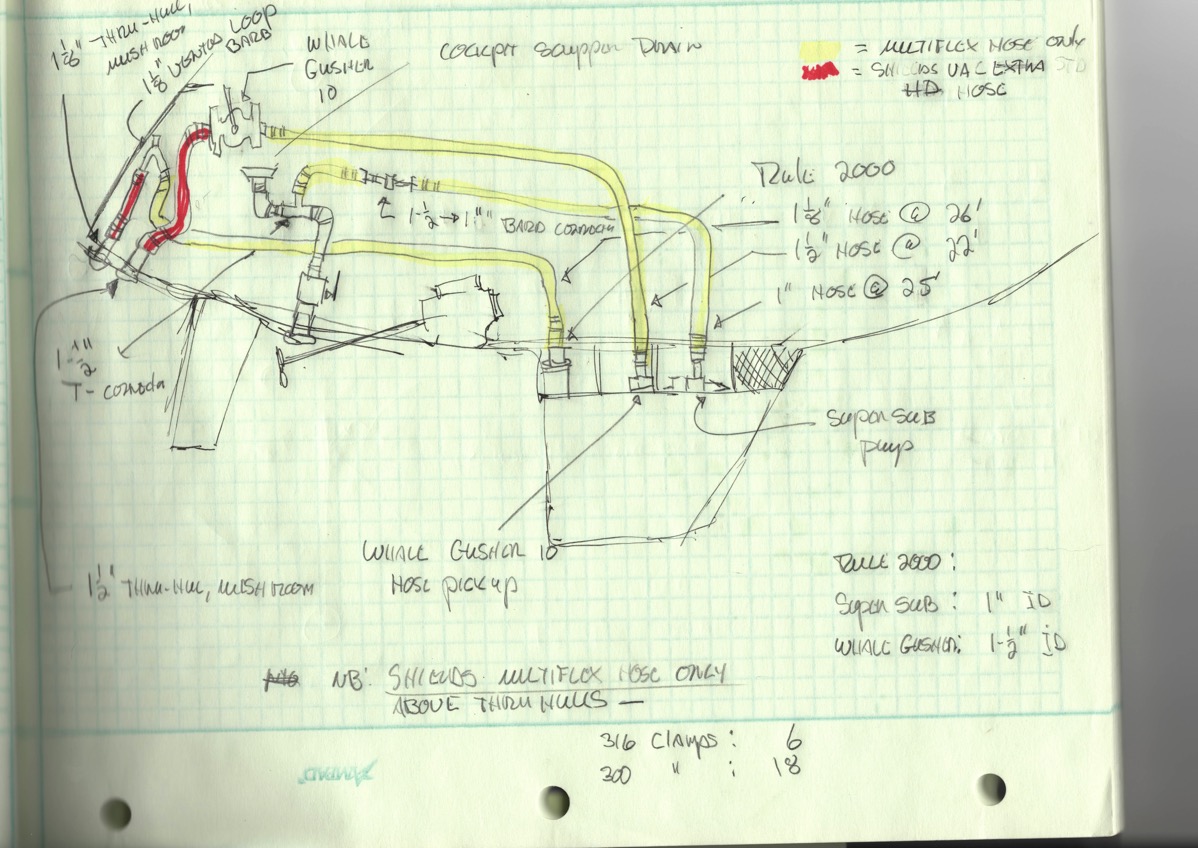

First thing that I knew I needed is a list of materials. I sat down and started with simple line drawings of the 3 basic systems and then got “creative” on the second iteration. In that plan I scoped out each length of hose and its diameter, any connectors and thru-hulls required, the pumps and types of hose clamps. After refining that a few times and finding simple mistakes I had my list of materials.

I gave the list to Charlie at the boatyard in the hopes that I could get some business steered that way but they had a hard time with some of the pricing. So I went out to some of my regular sources and started ordering. I should have most of the items this coming week.

On thing’s for sure, I going to have a good bit of bilge hose left over. In one case it was cheaper to buy an entire single 50’ roll for about 22’ and in another the 50’ roll price was exactly the same as buying 26’, each on a per foot basis. Maybe I’ll have some use for that hose in the future.

Not to scale:

From there I returned to the new storage under the port helmsman’s seat project. I cutout and hot-glued together a box section of 1/4” luan plywood and gave it a quick test fit. It fit, perhaps even a bit loose. Once I was convinced of the feasibility of the modification I ordered up some 3/16” thick FRP sheet stock from McMaster-Carr. That order will show up this coming week also.

Crude but effective:

Slots in nicely:

The real planning effort, one that I have rolled around in my head for quite some time without any great ideas springing forth is the hardware and rigging updates for the decks. This has to be done before I can start painting the decks and I’m pushing to get that going sometime in late May.

The boat has had a really jury-rigged setup for years and I’ve told myself that I would make it right. The problem is that I am not a really good “ideas” guy with it comes to this sort of thing. I’ve worked with pros and it’s clear that I’m not one.

One of my primary goals has been to reduce the number of lines led aft to the cockpit in an effort to reduce clutter. As I’ve said, we don’t race this boat so quick and efficient line-handling isn’t critical. I was hoping to go from four cabin mounted winches down to two. That idea didn’t survive the hours I spent moving loose hardware around and running string to simulate line runs.

In the end, it was clear that I would need to bring the old Barient non-self tailing winches back to their original placement. And here’s the best part, I now have even more lines led aft. Clever...

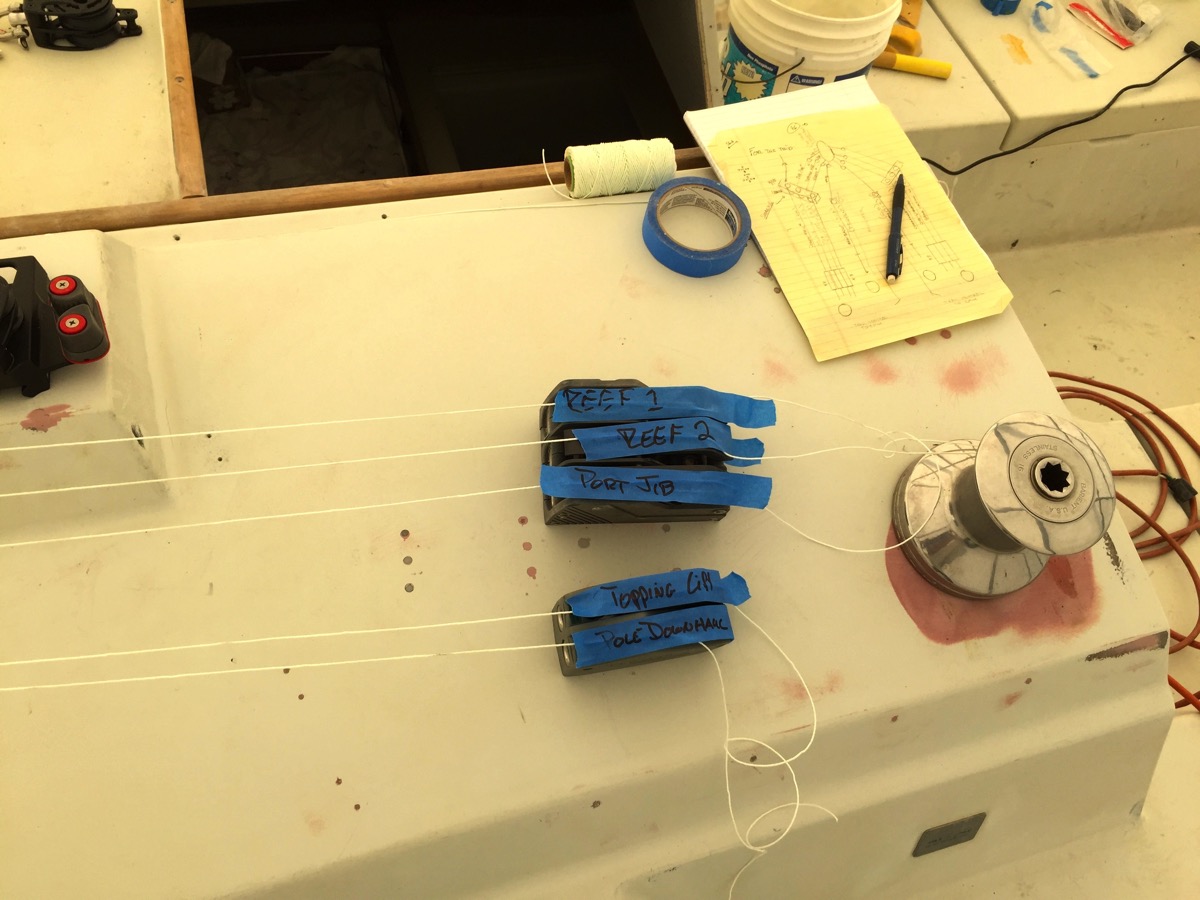

Just keep at it:

After taking notes on the layout I spent an afternoon working up a rough schematic of the lines and equipment needed. That forced me to undertake an inventory of all the hardware that I had on hand. Some of it came off the boat and some was sitting in boxes in my shed.

Hope I didn’t cross lines:

Original hardware from the factory.

Some new and some newish:

When I wasn't working on the boat project I did do some fun stuff.

Ninth Annual Sock Burning Party:

Not quite 16 knots. Next time...

Early start.

Early start.