I finished the taping and masking yesterday at 3:30 PM yesterday. Even though I was pressing to get the boat ready to paint today, part of the day was taken up with conferring with the rigger. He and his partner showed up at the yard around noon and we went over the mast. He’ll get back to me with options and pricing for the work. Which is just the way I like it. We traded boat disaster stories which is always fun.

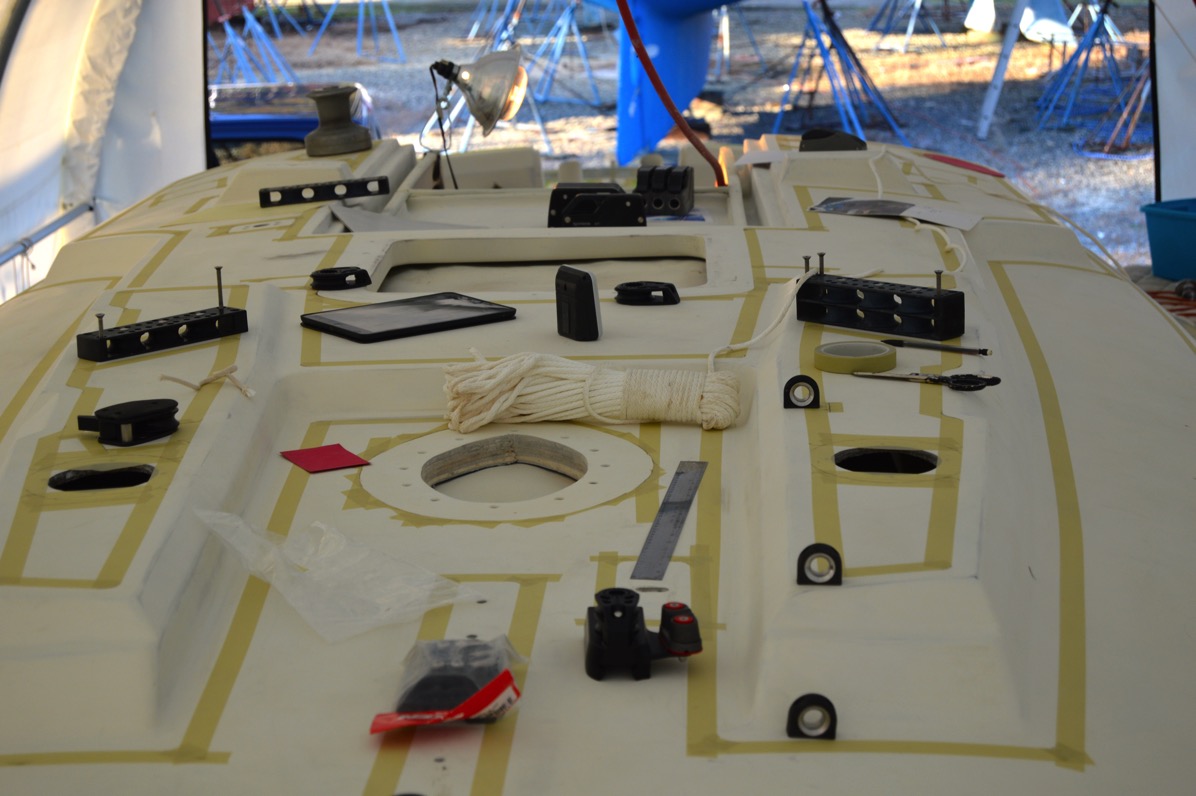

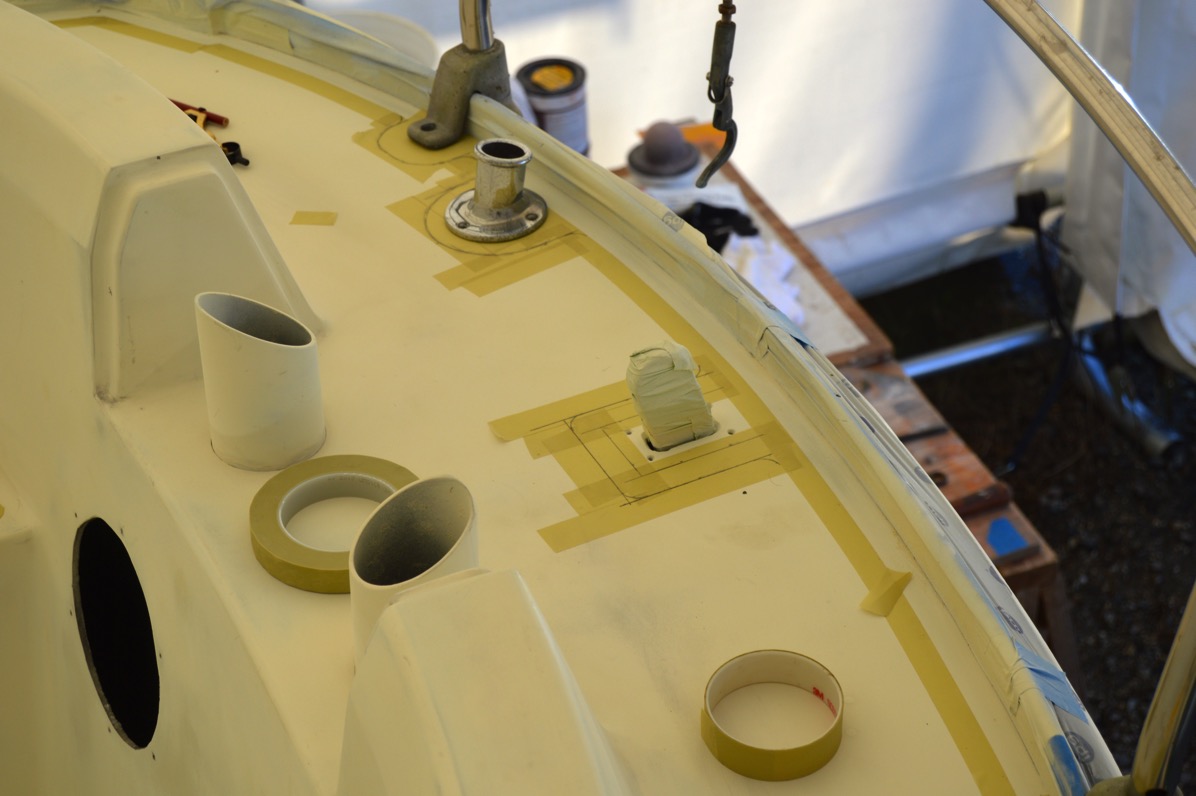

Last of the taping.

After getting home I had some dinner and the spent the rest of the evening getting all my gear together for painting. This morning I went over to my friend’s house and picked up his generator.

Arriving at the boatyard around 9:00 AM today I started laying out the materials and equipment. As I suspected, the shed ceiling was dripping with condensation and the decks were moist, to put it mildly. I set up a couple of fans to help with airflow and wiped all the surfaces with rags to speed drying.

Sill, it wasn’t until 10:30 that I could start in on the pre-paint deck prep. I vacuumed the decks for the millionth damn time, made a few quick repairs to taping mistakes and then started in on the two-rag solvent wipe-down. After that it was time to mix up the Awlcraft 2000 and let it induct.

By the time I jacked the spray gun in and started at the bow, it was 12:30. I knew right then that I’d be finishing near sundown.

I started out pretty nicely. Easy to lay down the first coat with no problems. Man, I thought I was gonna breeze right through this job.

Yeah. No.

Started well...

What with the fact that I had to contort myself in weird positions without ever being able to stand up straight, my back started to spasm. Oh joy. Add in me wearing these damn booties that kept pulling off my feet and the quality and ease of the work began to fade. If I had a dollar for every time I looked down after stepping in fresh paint, well, you know...

Anyway, I kept at for for three passes. Finished up around 4:30, cleaned up the gun and policed the job site and that was that. Took a few photos in the dimming afternoon light and headed home as the front started to move through. I managed to get the paint on before the season shut me down.

I was pretty happy about that, getting a major task finished. Pumped really.

Next up is to take a day or two off, eat something other than chili or bean soup, meet my wife who’ll be coming back from three weeks in Barcelona. After that I’ll start in applying the non-skid paint areas.

Final product.

I’m going to take some better photos tomorrow. You know, the ones showing the shiny glossy paint. With the bugs and footprints in it...