I awoke this morning to the sound of rain beating on our metal roof. There are times when it is a comforting tattoo that signifies a quiet day of coffee in bed, catching up on the goings-on the world (via the Internet...) and finding some small chores around the house to work on.

Not today.

I rolled out of bed early, put on boat-yard clothes, grabbed some breakfast, checked the NYT and then started to load the yard-truck with the required tools for the day's effort. I did a quick run down the street to check in with George Butler to make sure the skiff was covered and dry. Check.

Next stop was “Ronin”. Despite being a dismal drizzly and rainy day the temperatures were in the mid-sixtes. I unloaded tools and set up the work table. The goal was to sand off more AwlFair compound, check for imperfections and continue on the iterative process of getting the decks ready for priming and painting.

Grey day.

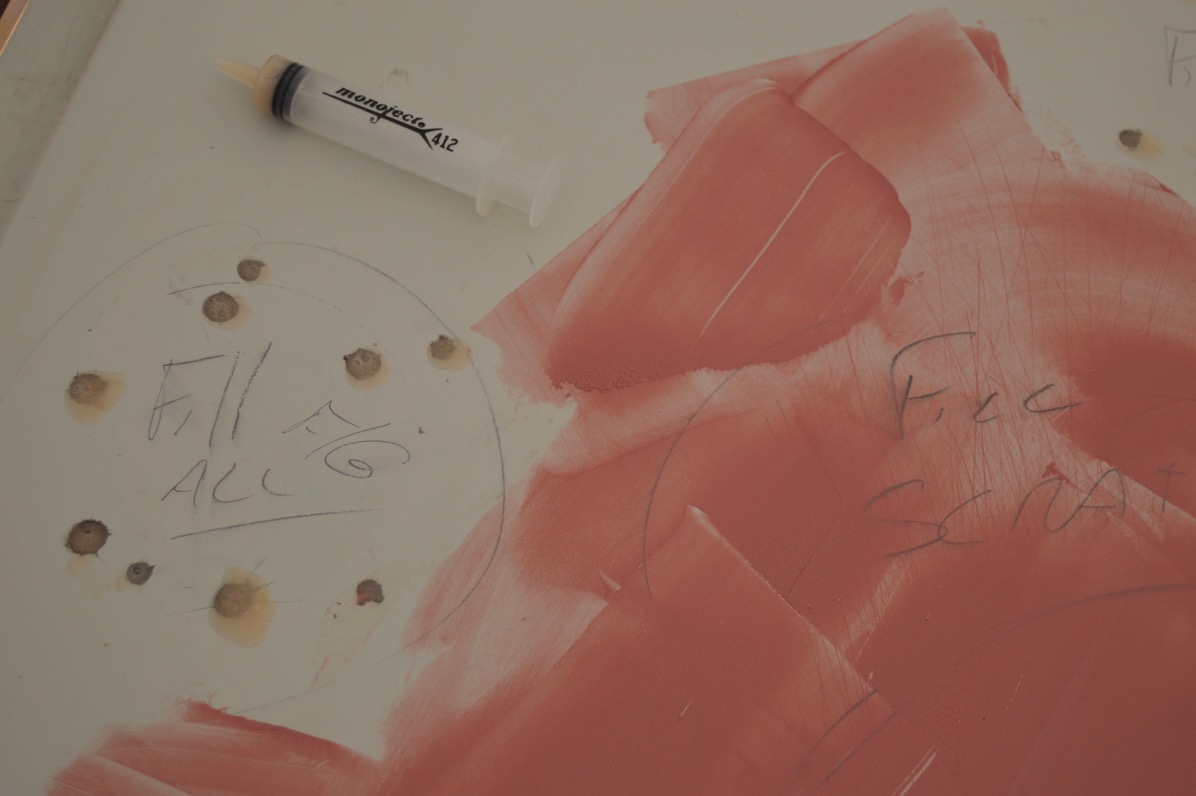

First thing was to identify those spots that needed sanding and more filler. I grabbed my new LED work light and went around the decks hand sanding the smaller spots. I had filled the hardware holes a few days earlier with West System epoxy and a little bit of micro-fiber filler. At the same time I worked some AwlFair into low areas and scratch marks.

Plugged and some fairing.

Wooden dowels to stop the epoxy leaks.

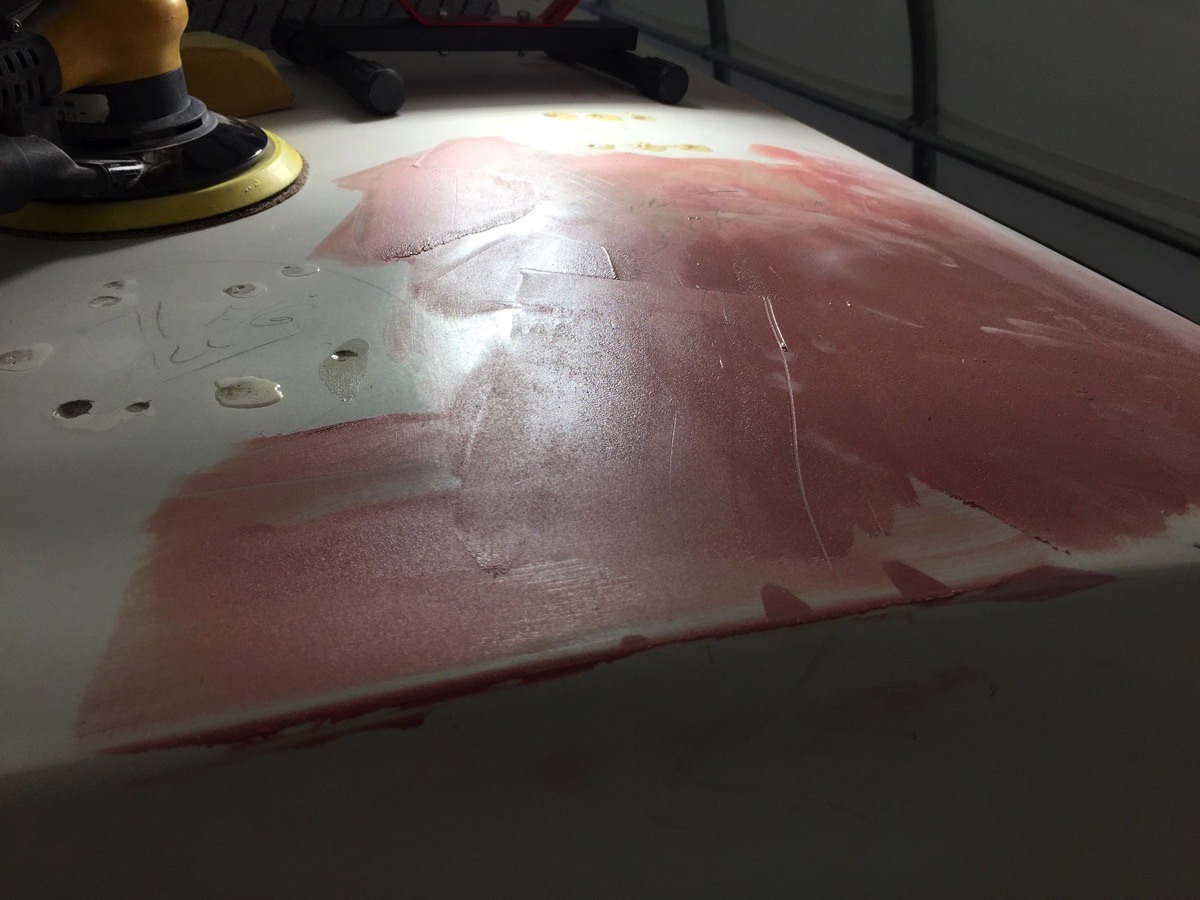

After that I spent some time working the board file on the cabin-top near the cockpit to get the area fair. Still not done yet but getting there.

Before and after:

Up front in the bow there was an area that had a bad layup and probably some hits that destroyed the deck where the anchor line ran. I had worked up a couple of applications of West System with microfibers to build it up. I machine and hand sanded the buildup.

Ugly epoxy layup.

Sanded, faired and AwlFair applied.

The next effort for the day was to prep the old quarter-berth hole for patching. I measured the opening, adding a few inches to the diameter of the backing plate. I cut the backing plate out of some scrap wood that I had lying around the shed but quickly found out that the gap between the hull and cabin liner was pretty tight.

Where’s my compass when I need it?

I ran the 2” pneumatic sander along the edges of the filler plate to make if fit. The problem was that it was thicker than than the opening available to me. Next step, fit it.

When I went to put it in place,the plug didn't even begin to slide into place. So, since I was going to have do some glass-work to finish off the ragged hole at the base of the quarter-berth I cut it away at the interior liner.

After getting the plug to fit I wrapped it with Peel-Ply and maneuvered it in.

Ready for epoxy.

The day was getting on and I decided to wait until the next session to finish the repair. I’ve learned to never rush a task.

No comments:

Post a Comment