As part of the re-wiring job I budgeted for all new battery management controls to replace the original Off-1-2-Both Master Switch. Since I was well on my way to being Blue Sea Systems customer of the year, dryly noted by Clark Beek of “The Adventures of Vessel Condesa” blog when I sent him some photos of the electrical work I was doing on Ronin, I opted for the new, “foolproof” Dual Bank Battery Management Panel. At the same time, I used the recommended Automatic Charging Relay (ACR) so the both banks would charge while underway.

The ACR senses when the system is charging and automatically charges both banks. When sailing and the the motor is off, the system isolates the banks and ensures that the starting battery is not being used.

The attraction of this system was the fact that I could just switch the position indicator to On and not worry about whether one bank was being charged at the expense of the other or worse, that while sailing all day drawing current with the battery switch set to Both that when it came time to start the engine I didn’t wind up with all the batteries drawn down. Another position on the new panel allowed that in an emergency both banks could be combined manually.

This wiring job was also part of the starting battery locker job that I talked about in previous posts.

I removed the original battery switch, a cheap push-pull bilge pump switch that a PO may have installed and the light-switch style Master switch which I never felt comfortable with. Too easy to knock it into the Off position coming down the steps.

As mentioned early, the original wiring was in pretty sad shape after fixes by both me and previous owners.

I grabbed the templates supplied by the manufacturer, taped them up and once satisfied I pulled out the Wonder Tool, the Fein Multimaster and got to work cutting the openings.

The new panels positioned nicely over the old locations with the exception of the hole drilled for the bilge pump switch. I’ll search around for a nice decorative plug for that at some point.

Dry fitting the panels:

The old master switch slot is now expanded and used for the ACR switch. New models have down away with the manual switch.

The old master switch slot is now expanded and used for the ACR switch. New models have down away with the manual switch.

The new battery management panel contains the boat master switch and two continuously one breakers for bilge pumps and two empty slots for other duties as needed. Nicely thought out.

Once mounted I started in on the wiring.

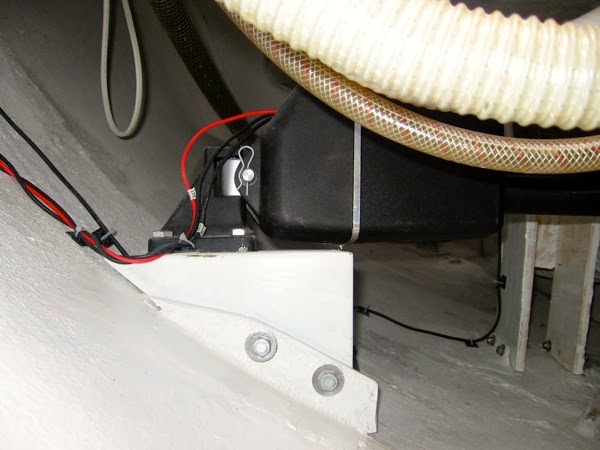

In the photos above the new battery cables haven’t even been run yet. The photo below shows the interior at a later time as more wiring and battery cable pulling was being accomplished.

I’ve hooked the system up to the batteries for a quick test and it all seems good. So far...