Progress on the boat: not a whole lot. Progress on the rebuild project: a significant step forward.

I’ve been out of town/working on other projects/Spring jobs around the house and generally trying to line things up to start in on the next large scale task, painting the decks.

The 14’ X 45’ X 16’ fabric and steel shed that I ordered back in late April was delivered to the yard. After waiting out some inclement weather I hired my neighbor and friend Skip, along with his construction crew to erect the structure. Looking at the instructions made it pretty clear that it was not a one man, one day job. They did a good job of erecting the frame while I was away in Northern Virginia.

Jungle gym and new-to-me toy in the pickup:

Another couple, good friends and neighbors, showed up early in the morning to help us with covering the shed. Again, it was not an easy job but the results were good.

Attach Tab A to Slot 3:

One oversight of mine was that I “assumed” that both ends of the shed would have opening doors. Not so much. One was a roll-up and one was solid. This is going to be a problem when it starts to warm up. I called the company and after discussing the issue with them, I think that I am going to have to purchase another opening end panel. In this case, I’ll opt for the cheaper material, store the solid panel and offer it as an “option” when I sell the shed.

Nonetheless, having the boat indoors, dry and protected is a big plus for being able to work efficiently over the next year. I already have plans for a large fan, a diesel heater for cooler temperatures, a cooler, a couch, flat-screen TV… Umm, no, scratch the latter three items. Need to get some work done when I’m there.

Snug, dry and unfortunately, very warm:

Today I started out expecting to get going on deck work and setting up the work environment in the shed but I got a call that our Mako 261 would be ready to go. I had taken it to another local yard to have the impellers replaced and lower unit oil changed as preventive maintenance for the summer season. Given that it was out of the water I decided to make it a day of buffing, polishing, waxing and cleaning boats. Ergo, both boats got a sprucing up.

“I know that I have a 9/16” socket here somewhere…”

"Wax on, wax off…”

Thunderstorm coming? No problem, I’ll go work on Ronin in the dry shed.

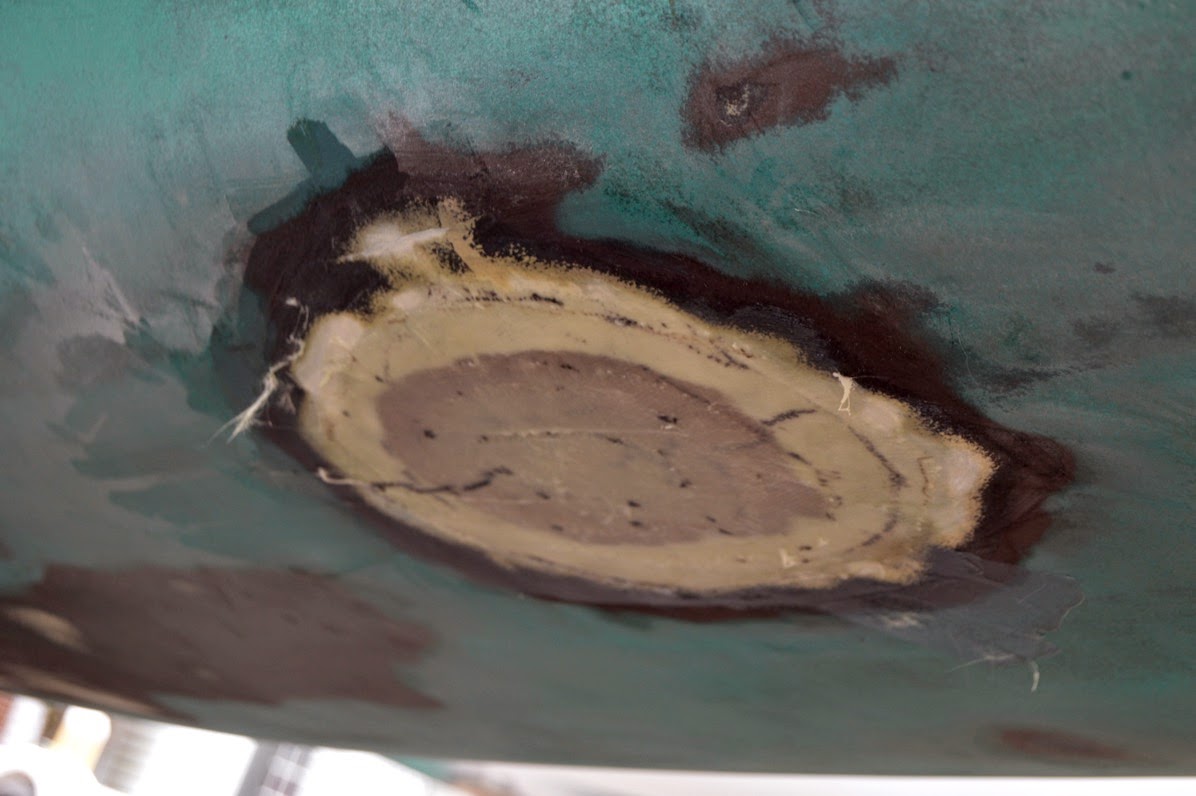

The last scrub-down of very, very tired old gelcoat. I hope.

As lagniappe, a photo of the inspiration for the paint color that I chose for “Ronin”, the old 12-Meter Columbia.