I’ve been mostly working on small things for the refit, finishing odd pieces of the cabin sole that need special attention, applying the final coats of satin finish over the coats of gloss AwlWood to the large cabin sole sections. When those were complete I wrapped them in construction paper and put them up for storage in shed.

The Butler skiff had been sitting on sawhorses at the Railway. I decided that rather than splash it, drag it back to the slip and worry about keeping it floating over the winter that I would just store it there. The yard owner fell 6 feet of a strong-back the broke and was out of commission for a week or so. This week we moved the boat, flipped it over and I wrapped that up for the winter too.

All it needs is a nice red bow.

Before Christmas I spent some time cleaning the bilge. Originally I thought that I could get it ready to paint by simply scrubbing the 33 years of crud using household cleaners and a stiff brush. I was disabused of that idea pretty quickly. So, my fallback method was to bring out the heavy equipment. The power washer. I picked a day that was raining, put on old foul-weather gear and after cleaning with Simple Green and letting it work a bit, I started in.

Not a job to be taken lightly. I blew crud and crap all over the boat. But, it did the trick. There was dirt, dust, old stainless steel hardware and fiberglass bits that came out of every crevice in the hull. I crawled down into the cockpit locker and cleaned the seldom seen areas around and behind the rudder and quadrant. It took 3 days just to dry out properly.

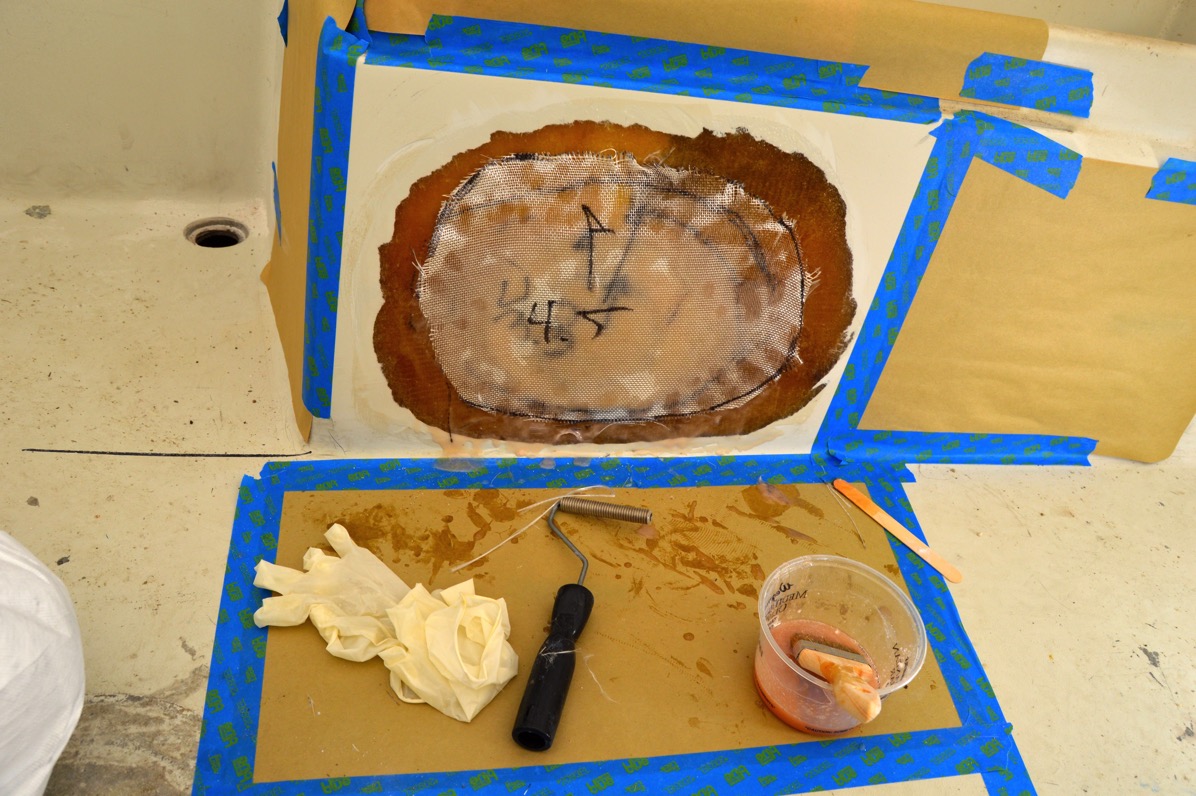

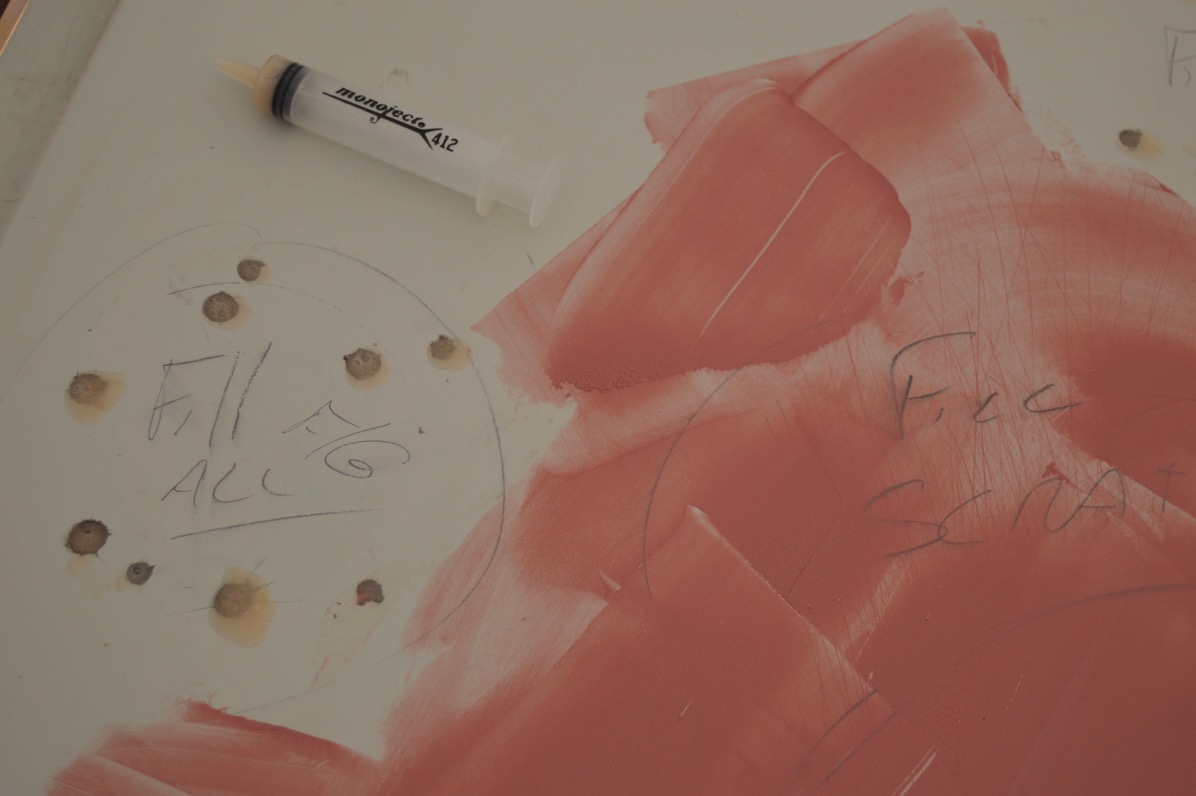

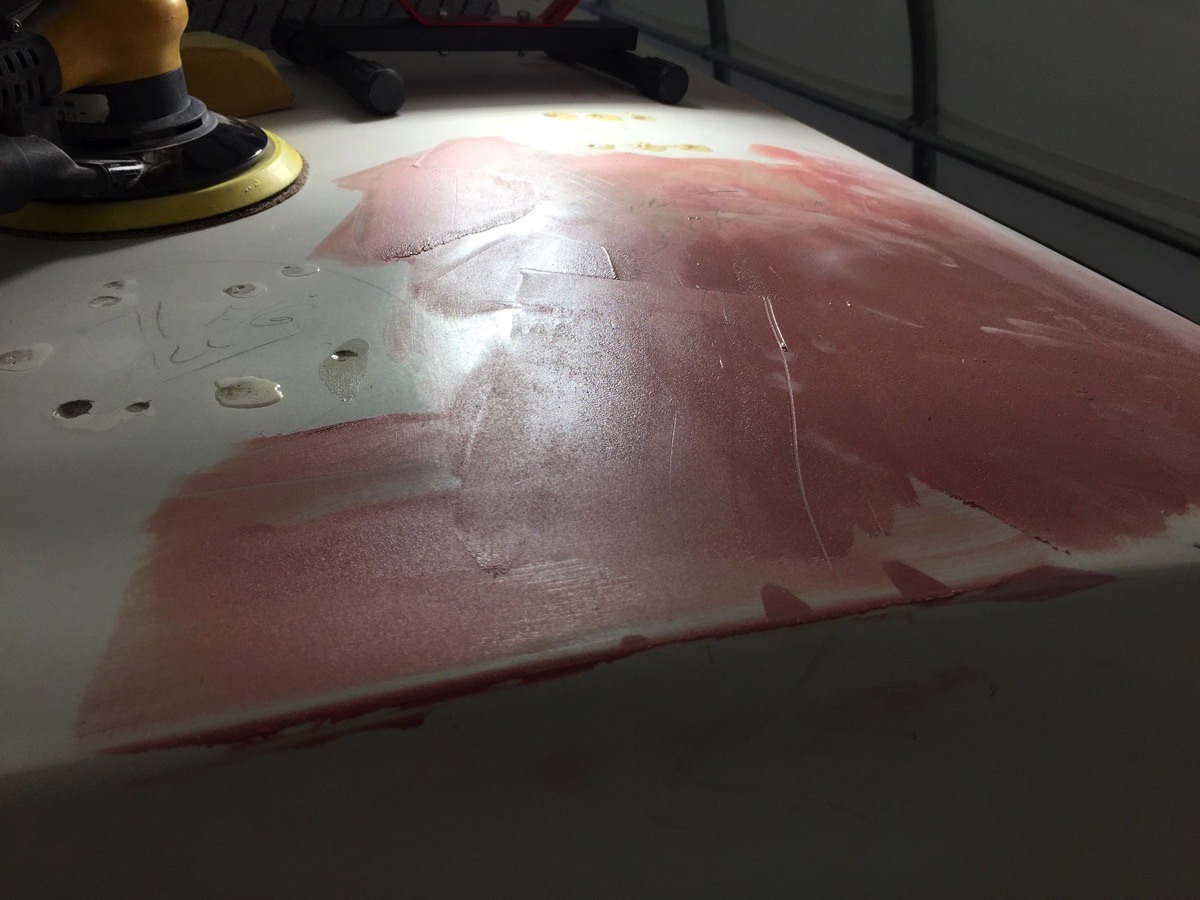

After that I spent 3 days sanding, grinding and scrapping old paint and caulk. Another afternoon spent washing all the surfaces with thinner and I was pretty much ready to go. I took one day to tape up all hoses, lines and exposed surfaces.

Today I donned my Tyvek coveralls and went to work with rollers and brushes. Not an easy job because I had to spend most of my time on my knees and bent over. At the end of the day I had one coat applied.

Getting started.

First coat on and drying.

I may have mentioned in another post about the interesting boats in this yard. A “unique” sailboat showed up a week ago. I was intrigued and walked around it admiring it for a good 15 minutes before it dawned on me what it was. A “modified” Cal 25. I used to own and race one in Annapolis. Stunning.

Years ago I was fortunate to be able to do a tour of a Cal 40 being completely rebuilt and upgraded for racing with the late designer Bill Lapworth. He was firm about the reasons for some of his design elements and felt that changing them might be a bit of overkill. He would not have approved of this change.

Somewhere in Heaven Bill Lapworth is weeping...