When I last left the deck painting task I had just finishing spraying the gloss topcoat. Even though I knew that I would probably get locked out by the falling temperatures I wanted to keep going as much as possible on the deck paint task so after pulling the tape and the paper, I started in on counter-taping for the definition of the non-skid areas. I probably finished about three quarters of it before Winter set in.

I decided to leave everything in place and come back in the Spring to finish off the non-skid application. One decision was to leave the tape in place. I discussed this with a couple of painters and got differing options. Leave it it place because it wasn’t exposed to UV. Pull the tape because it would harden up and become difficult to pull. And lifting old tape might take some paint with it. I went with leaving the tape in place and avoiding re-taping the same areas again in the Spring.

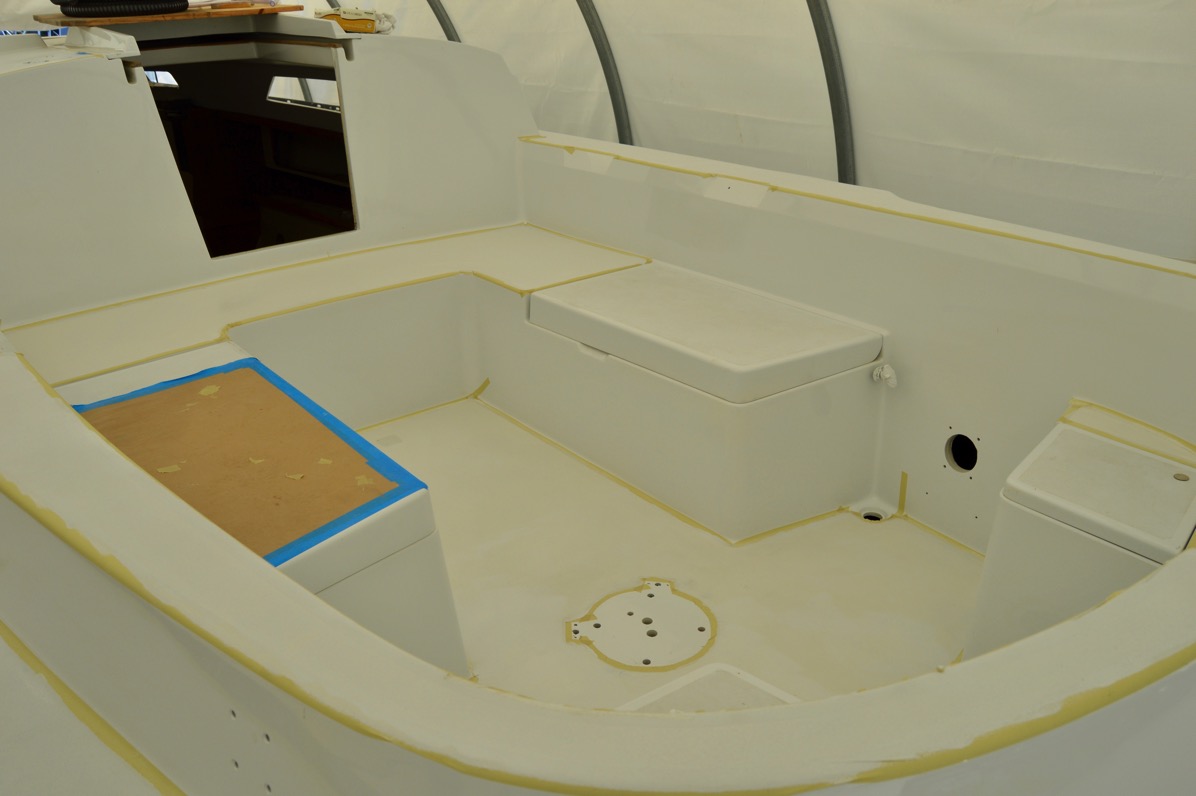

I returned when the weather warmed up in May 2017. I finished taping the boat in order to apply the non-skid. I decided to use the AwlGrip recommended technique of rolling on the paint and “salting” the Griptex into the paint. This technique is nicely described as the best way to go for rank amateurs like me.

Actually, I had done some test panels last year and I thought the results were pretty good. I followed the instructions to roll on the Awlcraft topcoat. I used a 4” rounded-edge foam roller to apply the Awlcraft. I then came back with the Griptex, in a large plastic yogurt container with a bunch of holes punch in the lid and used the “salt” application method. The key is to keep shaking. That ensures that it covers evenly. After doing that I let the first coat of paint and Griptex sit for about 30 minutes then rolled another coat of Alwcraft. Waiting another 30 minutes I “salted” more Griptex, mostly to ensure that areas that may have been a bit thin were adequately covered. After yet another 30 minutes I rolled a third coat of Awlcraft on to seal the Griptex and take some of the edge out of the non-skid.

First coat of non-skid applied.

Better photos of new non-skid.

One of things that I decided to do when repainting the decks was to upgrade the look of the deck. On Ronin there was non-skid everywhere. If the surface was horizontal, it had non-skid. If it was vertical is was painted gloss. As part of my obsession with turning a sow’s ear into a silk purse I decided to delineate the deck edges and hardware pads so that there was a glossy relief around each item. For instance I added a 1” gloss strip adjacent to the toenail which had never existed before. Eh, why not?

Kinda hard to see the fancy edging...

I was pretty pleased with the way it came out. But that was before I started to clean up.

Well, it turned out that when I started to removed the tape and paper the 3M tape all came off quite nicely. Good clean lines. However, in three areas, a good bit of the gloss topcoat lifted right off. On inspection it wasn’t the problem of leaving the tape on for too long. It seemed pretty clear to me that I had not prepped the surface well enough before laying down the topcoat. Large sections of perfectly sanded yellow epoxy primer were exposed. Dang.

Not quite the effect I was hoping to achieve.

Exasperated, I just kept going knowing full well that more painting would be involved. Since I’m not charging myself for the job I wouldn’t be “losing" money, only my patience.

After re-covering the entire hull I sanded down the affected areas and back-tapped prior to shooting. Pulled out the mighty 3M spray gun and applied another coat of Awlquick primer. I let that set up for a couple of days and then came back and sanded with 320 grit for adhesion. On a good day with temperatures in the low 80’s and low humidity I resprayed the exposed areas with Awlcraft 2000. When finished I felt pretty good about my efforts yet again.

Fix it again….

Looks good in this light.

When I came back the next day and pulled the plastic and tape I saw that I STILL had not gotten it right. I had used a different sized (smaller) tip in my spray gun and at the same time adjusted the thinner, using a bit more than the original spray job. The result was that although the paint flowed out more evenly and better than the original effort, the film thickness was too thin. Compared to the original paint the yellow of the primer in the respray areas was evident. Dang. And dang again...

So, as is my wont, I took the summer off and did other things. Spain, Slovenia, sailing in the Adriatic off Croatia. Riding.

I’m now just getting back to fixing the fixes.

Green tape marks touch-up areas….

Anyway, I was out at the boat today and a gentleman who bought an original Cal 40 found in the yard and is now in the process of restoring came by to chat. Asked when I thought I might have Ronin in the water. I gave him my standard reply to that question: One and a half years. No matter when I’m asked...