I’m trying to spend more time on the refit project especially with the favorable weather that we’re having. After getting back from the Dominican Republic I have redouble the final effort to put on the Awlquick primer and sand it in preparation for applying the topcoat.

I knew before leaving that there were some serious mistakes that I had made fairing nicks, gouges, cracks and glasswork in preparation for the gloss topcoat. The number of those mistakes were a bit depressing. Especially after I came back and and filled them with Awlfair. I sanded all the builtup fairing compound and applied more Awlfair, let that set up for a day and then sanded again. After doing this I mixed up another batch of Awlfair and spot sprayed.

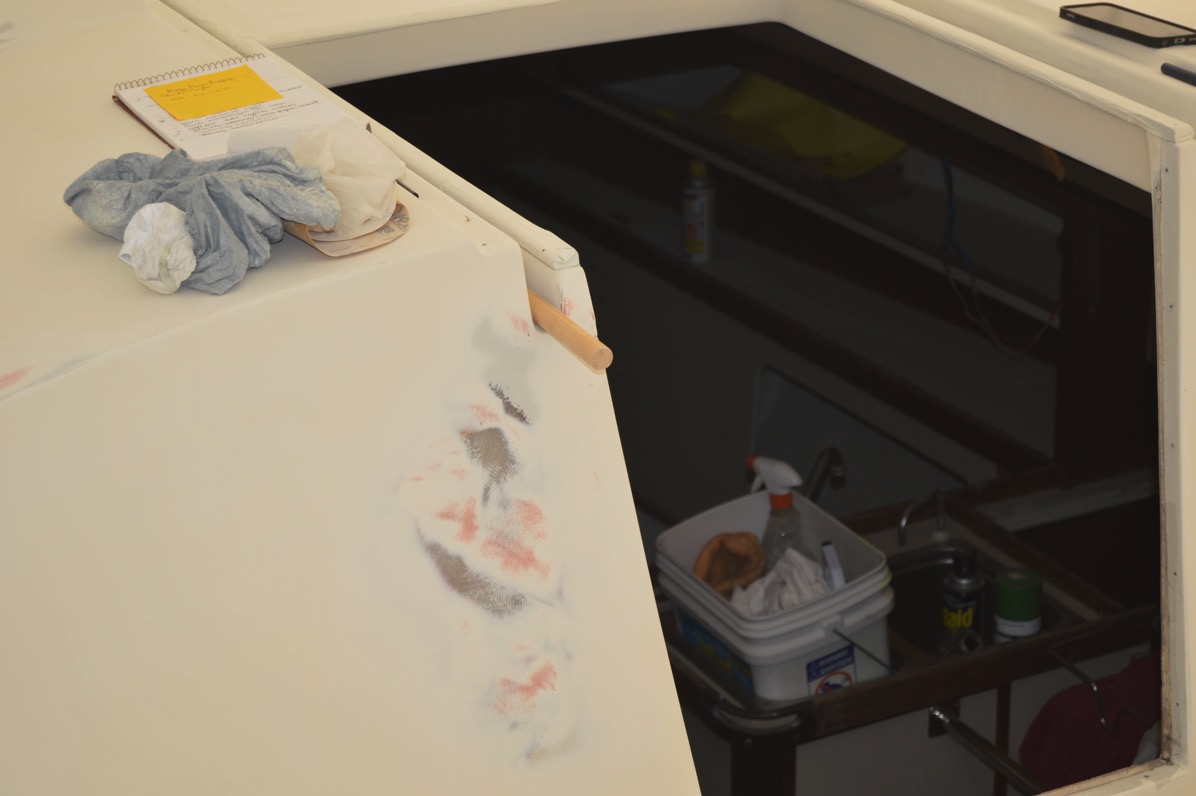

Fix those cracks and scratches.

And lo and behold, more pinholes appeared. Some in areas that I thought I had fixed and some new ones. Frustrating.

Too tiny to see in the photo but they’re there.

One section of the port scupper drain showed another set of holes that had blown open next to an area that I filled. Closer investigation with a sharp knife revealed yet more glass layup failures. I should have really tested the entire length of the affected area to ensure that I repaired everything prior to spraying the primer.

Bad layup blown open.

The voids in the scupper drain required something more industrial. Out came the West System mixed with colloidal silica shoved into the opened cavities. This area would not be ready for sanding and painting within the day but I’ll just do that in the next day or so and “paint” that area with primer.

So, with just enough of the original gallon of primer left I tried a different tack with the pinholes. 3M Arcyl-White Glazing Putty. I should have used that earlier. It is easier to apply in small amounts and has the benefit of being ready for sanding after 30 minutes. I did a closer inspection of areas that I knew were suspect, smoothing on the glazing compound as I went. Sanding with 220 grit sandpaper was enough before painting.

Glazing compound. Should have used it sooner.

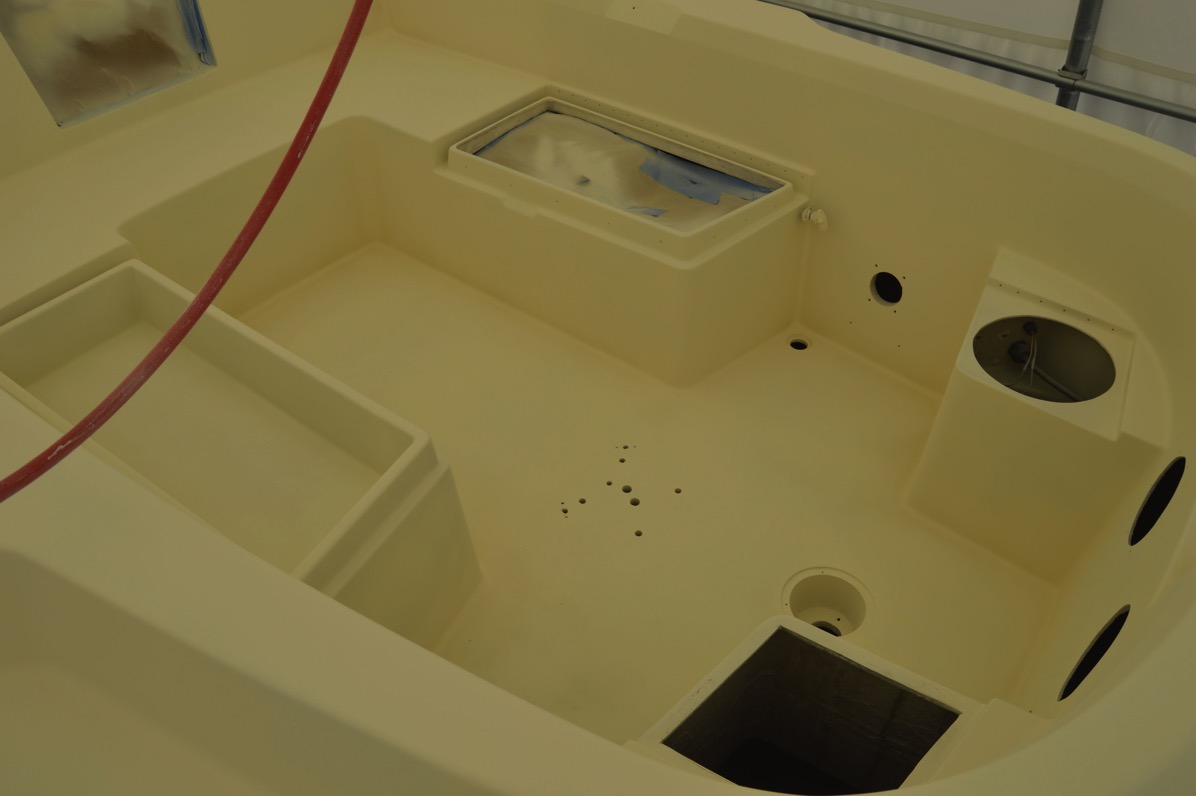

While waiting for those areas to set up I started in on final sanding the surfaces that will be painted with the gloss topcoat. I had already machine sanded the entire first primer coat on the decks with 320 grit sandpaper. The key to getting a nice finish with the Awlcraft 2000 is to final sand those areas using 3M Dry-Guide and more 320 grit sandpaper. Block sanding by hand.

Hand sanding the primer isn’t very hard and the results using the Dry-Guide are sublime but it does take time. I anticipate several days of that coming up.

Smoothing the surfaces.

Once the glazing compound set up and sanded I fired up the compressor, mixed the last of the Awlquick and applied covering coats.

More primer needed.

So, at the end of the day I am 99.99% done with applying Awlquick epoxy primer. Next installment, after I get back from four days of helping my brother and sister-in-law run a 3-day Endurance ride in Fort Valley I will finish the block sanding and start in on masking the non-skid and gloss patterns.

Covered.