I know that I’ve tried to post at least once a week with progress on the refit but as usual other things get in the way.

After getting back from my great Interstate excursion I received an emergency request to assist with timing duties in a weekend endurance (horse) race near West Virginia in the Shenandoah Valley. I spent a Friday, Saturday and Sunday standing in the cold and wet ensuring that the horses coming into the checkpoint were pulsing down to 60 BPM.

From there I ended up in Arlington for two days attending to some chores and catching up with one of my old bosses and her husband. Truthfully, I’ve enjoyed the days off from working on our boat.

However, that does not mean that I have not been working on boats. I have been. Other peoples (OP) boats...

I have two neighbors here in Reedville who have sailboats that either accidentally acquired holes in their hull or needed to have a couple of thru-hulls removed and glassed over. My friend, and the builder of our new home, Vincent has a Corsair F-24 trimaran designed by Ian Farrier that he sails every free moment he has. And I go along with him whenever possible. Flying along at 14 knots in light winds is quite the bit of fun!

Earlier this spring we had abnormally high winds and during a particularly windy day, his boat was blown of the jack-stands in his driveway while being readied for bottom paint. There was not damage to either of the floats but one jack-stand managed to put a 4” cracking the laminate near the rest of the main hull. Repair work was in order.

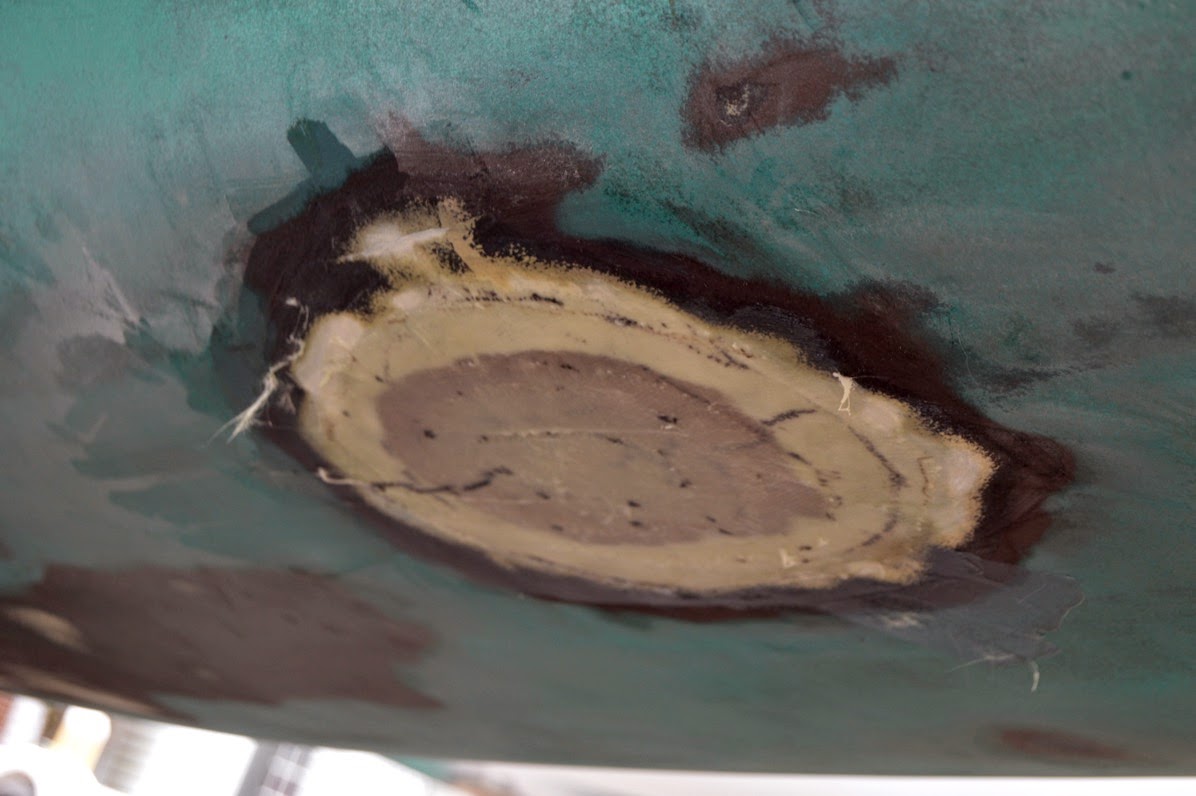

After having no luck finding a boatyard that could get to the repair within a reasonable amount of time, we decided to do the repair work ourselves. Over the past few days I have been working on that crack and another one found in the starboard float. Fortunately the damage was not too great and did not extend completely through the laminate. After grinding out the areas I worked up a schedule of 10-oz woven cloth for the punctured hull section and some biaxial cloth tape for the edge of the float. After applying the cloth using a slightly thickened mixture of West System and colloidal silica, I let it set up. A quick check today when the rain stopped confirmed that the fix was strong and ready for grinding, sanding and finish fairing.

For another neighbor and friend, new to sailing, we removed the non-function head thru-hulls and glassed the holes over. Since the boat will be used for afternoon sails in the creek and out in the Wicomico River, it made no sense to provide for a head. Illegal one at that...

Nice Cape Dory Typhoon with head thru-hulls glassed over and ready for bottom paint:

Fast Corsair waiting for more glasswork:

No comments:

Post a Comment