With the weather cooperating and after getting back from helping my brother and sister-in-law put on a 3-day, 100-mile endurance race in the Shenandoah Valley, I’ve been pushing to get the deck ready for the gloss topcoat application.

Over the years I’ve surfed the internet for examples of others painting their boats in order to get some sense of what I’m up against and how to go about it. It seems to me that all those guys get their tasks done pretty quickly and efficiently. That is not what I am experiencing.

I’ve spent two or three days just block sanding and machine sanding the primer with 320 grit for the final surface. My fingers are raw from digging into the corners and along the toerail. I finally started to “cheat” and use my Mirka sander because time is running out with the onset of the Fall season.

Protection is key.

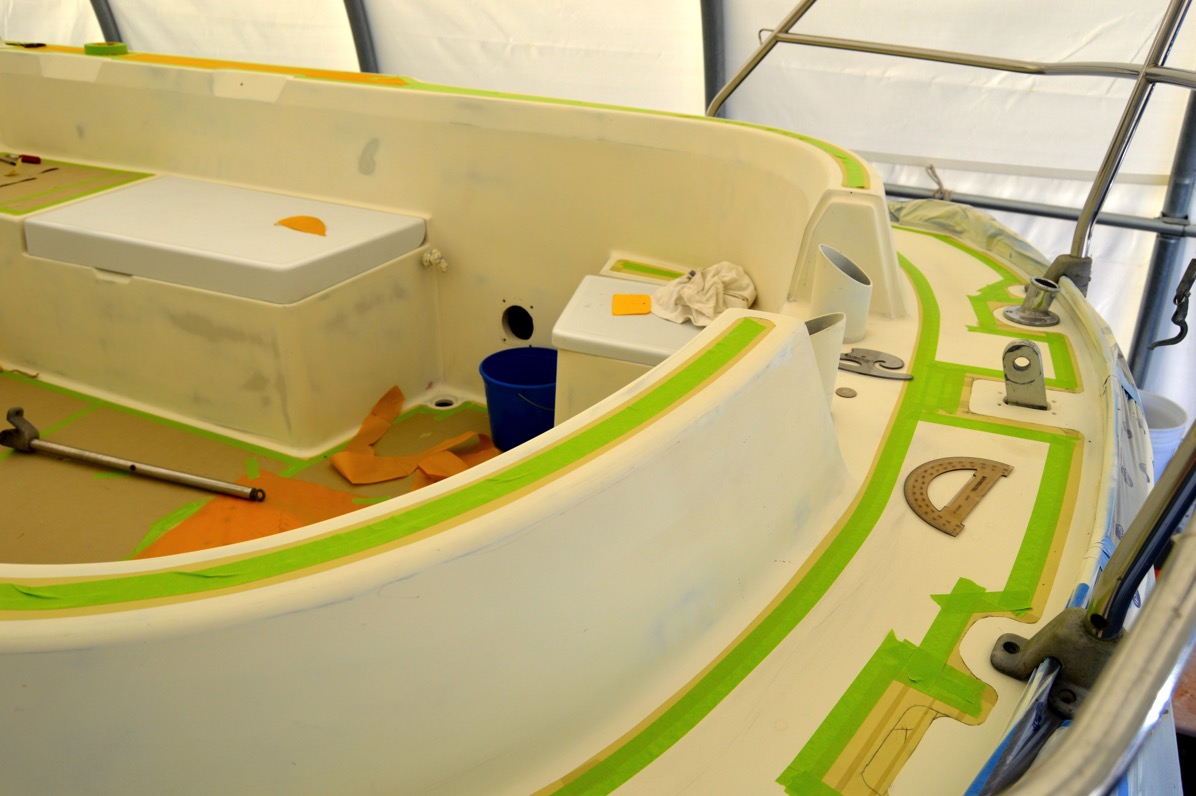

With the final sanding complete I did a quick vacuum and then pulled out the masking supplies box and got to work. I started with the cockpit sole because I was tired of grinding sanding dust and yard dirt into the clean sanded primer and wanted it protected with some sturdy paper.

Protected.

What to me seemed a quick and simple job took an entire afternoon. I knew right then that I was not going be spraying the gloss coat after three days of taping as I had planned.

Okay, I decided to take a deep breath and go into Zen mode. The prep work will get done when it gets done. The ace up my sleeve is that I called my brother and asked if I could borrow his 125,000 BTU diesel fired radiant heater. Confirmed. Just in case the temperatures dropped out before I could pull out the spray gun...

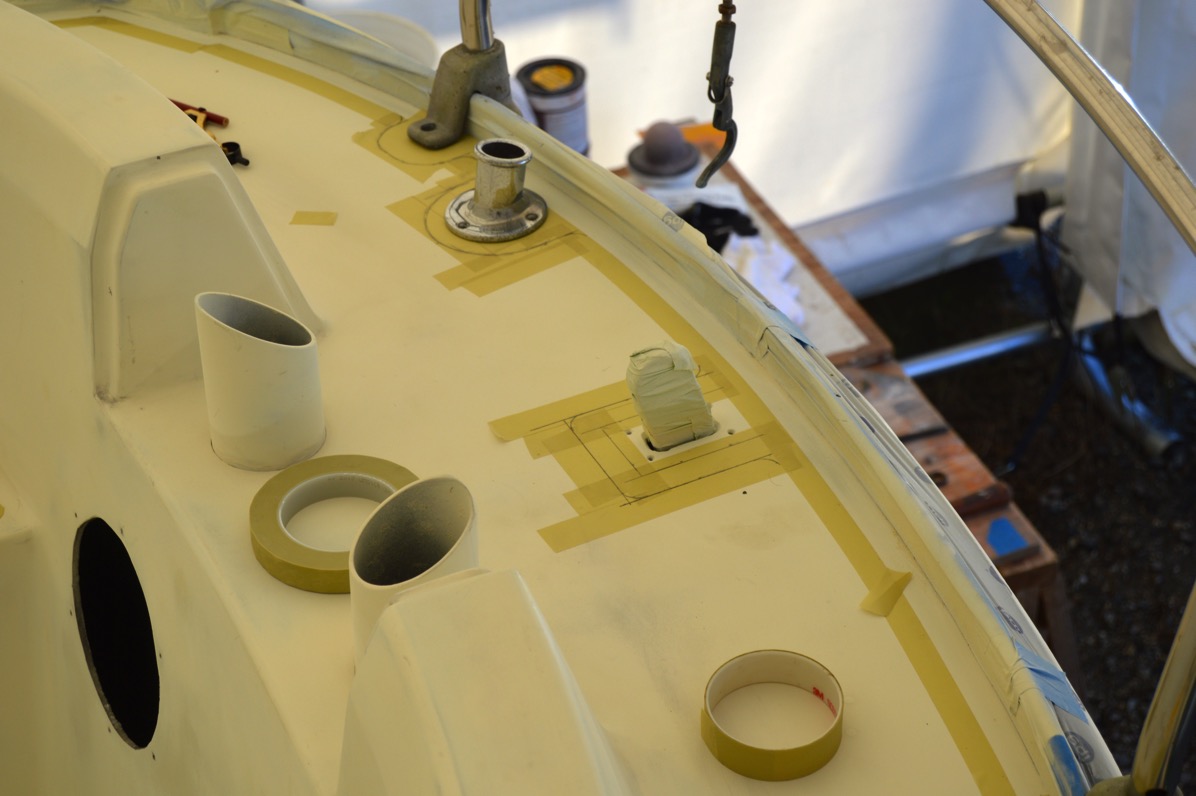

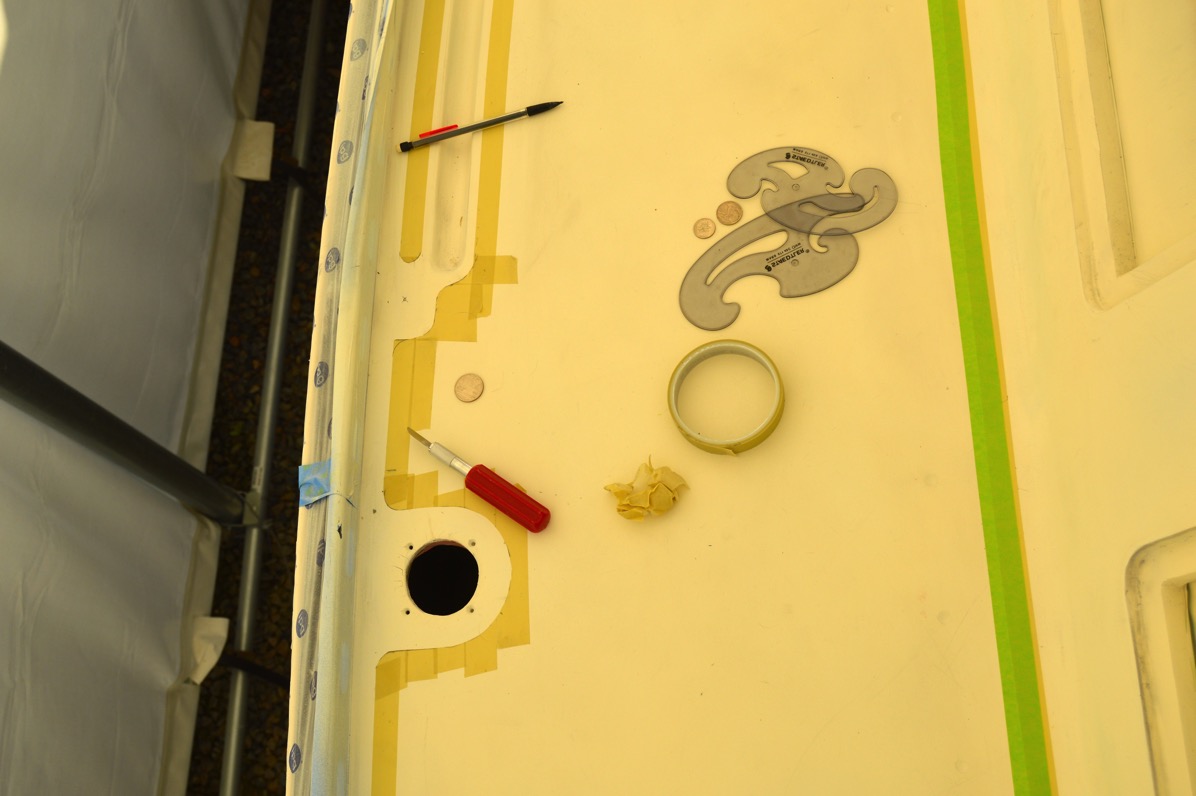

So, every day I get up, get breakfast, drive to the yard and start the very, very slow process of taping out the gloss areas with 3M 218 Fine Line tape. Lay it down, draw out the outline, cut out outlines for each stanchion base, cleat and mounted hardware. Incredibly time-consuming. It will take many days of this process. And my knees are wrecked.

I hauled the pushpit over to the yard and set it on the stern. With that in place I could outline the stanchion feet, flagpole base and an area for some miscellaneous wiring for the stern light and GPS antennas exiting the deck.

Why does the stern looks so small?

Old habits are hard to break. Every damn time I would climb up the steps to start into the cockpit I would grab the top rail of the pushpit for support. And every damn time it would start to rock back off the stern. You’d think I would learn...

More taping.

After about 3 days of work I am just finishing up running the tape up the starboard side. Lots of stops along the way to figure out the outlines for the gloss areas for the rest of the stanchion bases, diesel and water deck fills and the head pump-out deck fitting, a plate for the chainplate and the channel sides for the deck scupper drains.

Now, full disclosure; I have no one but myself to blame for this. None of those cutouts and fancy curves existed in the original deck layout. C&C simply sprayed non-skid over 90% of the flat deck areas. It was me that decided to sex it up a bit and add the gloss cutouts and line along the toe-rail. Some of the impetus for that was to make sure that any fittings were sitting on smooth surfaces so that there would be a good seal when I stared to put the deck fittings back on. And mostly because I just thought given all the time I’m putting into this effort I might as well make it look like a Hinckley.

Yeah, good luck with that...

One day’s worth:

As part of the project I’ve gotten in touch with a local rigger. He’ll be out in the next week or so to go over my list of tasks for re-doing the rigging. Looks like new rod and most certainly new running rigging, wiring and coax.

Sad old mast.

And I wished that we would just stay on Daylight Savings Time...

No comments:

Post a Comment