Since I’m not posting on a continuum here, I thought I’d add a short post about what I found while doing some deck repairs. It was “interesting."

One of the former owners had done or had someone do some “quick” deck repair to the areas radiating out from the inboard ends of the stanchions that are used for the gates. On our boat we have gates port and starboard in line with the cockpit bulkhead. As stands to reason, as people, including me, grabbed them to haul themselves up or just to get aboard, the levering action seemed to have really put a lot of stress in that area. I assumed that the fix involved replacing core and adding fiberglass but that appears to not have been the case. It seems that essentially someone just ground out the stress cracks, filled them in and did a quick paint and non-skid cover.

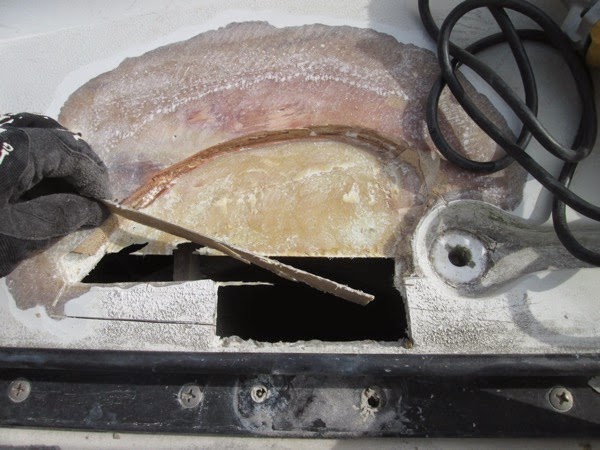

Port side deck at lifeline gate:

So after attacking the deck with my trusty grinder I discovered the good and the bad.

The Bad: It seems that when C&C built the deck it smartly designed it so that the areas that are on top of the hull are solid glass. Good idea in theory. But what seems to have happened is that as the deck layup transitioned/tapered from the core areas to the solid glass areas, the overall thickness of the laminate became very thin. So what happened is that the area was prone to movement throughout. Constant springing whenever the stanchion was pulled on.

I would guess that the total thickness of the deck at the area where it overlaps the hull, just before and under the toe-rail to be at best 3/8” thick. In the area where there was still some coring, in this case some very thin foam, the bottom laminate layup was exceeding thin, maybe 1/16”.

Initial grinding and exposure:

After cutting and removing the lower laminate schedule:

So, the Good News: the core was dry! Even the plywood that was used instead of balsa core. Not sure if that was put in at the factory or if it was part of the initial repair. From the looks of it I think that the factory used plywood...

Anyway, I ground out the area on a 12-to-1 radius, based on the thickness of the top laminate layer, cleaned every thing up and formed sections of pre-made 1/4” FRP and epoxied them into place as replacement for the 1/2” balsa core.

First layup:

While that section was curing, I moved over to the port side. Closer inspection lead me to believe that all that was compromised was the up level of the laminate that have a few stress cracks in it. It seemed to be a good bit stiffer that the starboard side so I decided to just grind out the area and re-glass it.

First look:

When I was finished grinding and cleaning the area I cut sections of biaxial cloth along with as small section of 10 oz cloth and epoxied them into place.

Layout and epoxiing:

More to come after the epoxy sets up. Waiting for the rain to stop...

No comments:

Post a Comment