Part of the refit job involves updating the plumbing. In my planning software under Plumbing are items that encompass things like through-hulls, seacocks, bile pumps and hoses, head and holding tank updates and fixtures. You get the idea.

Years ago while doing cabin sole replacement number one, I managed to run a screw right into the high-pressure supply line to the head while fastening the cabin sole in place. It didn’t take too much time hearing the pump along with its favorite sister, the bilge pump laboring away to figure out that I had a problem.

So, being the “let’s get’er done quick” kind of guy that I am, I simply cut out a section of the original grey tubing, fitted a section of clear Shields polyester reinforced PVC hose, double, double hose clamped it ‘cause I found out that single hose clamps on a non-barbed fitting, well, don’t last too long. The fix is under the floorboards so out’a sight, out’a mind...

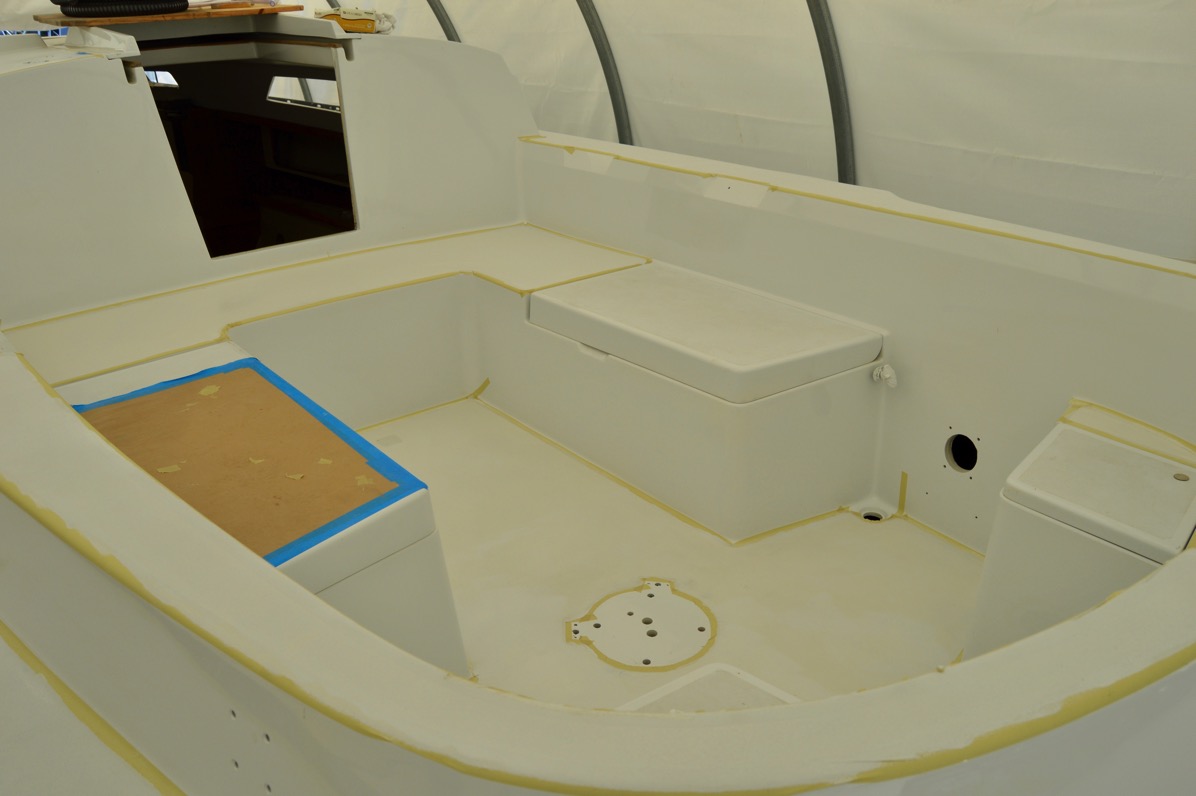

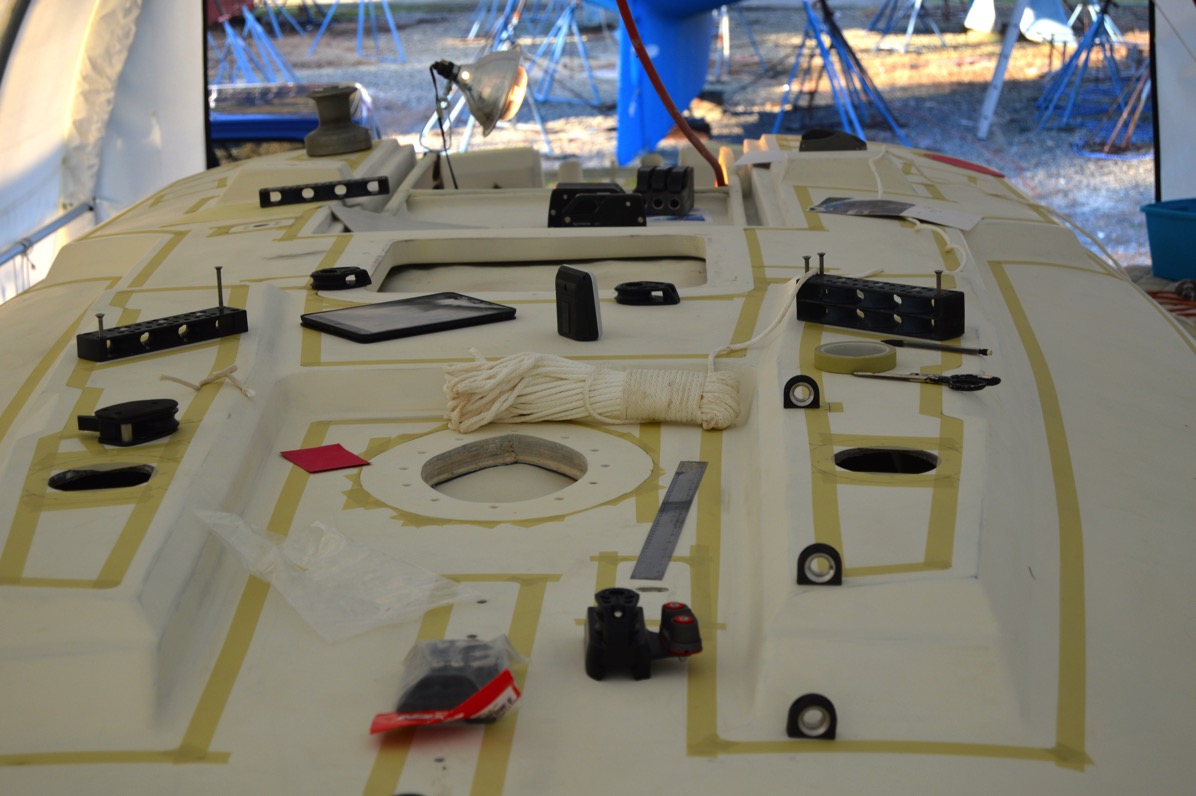

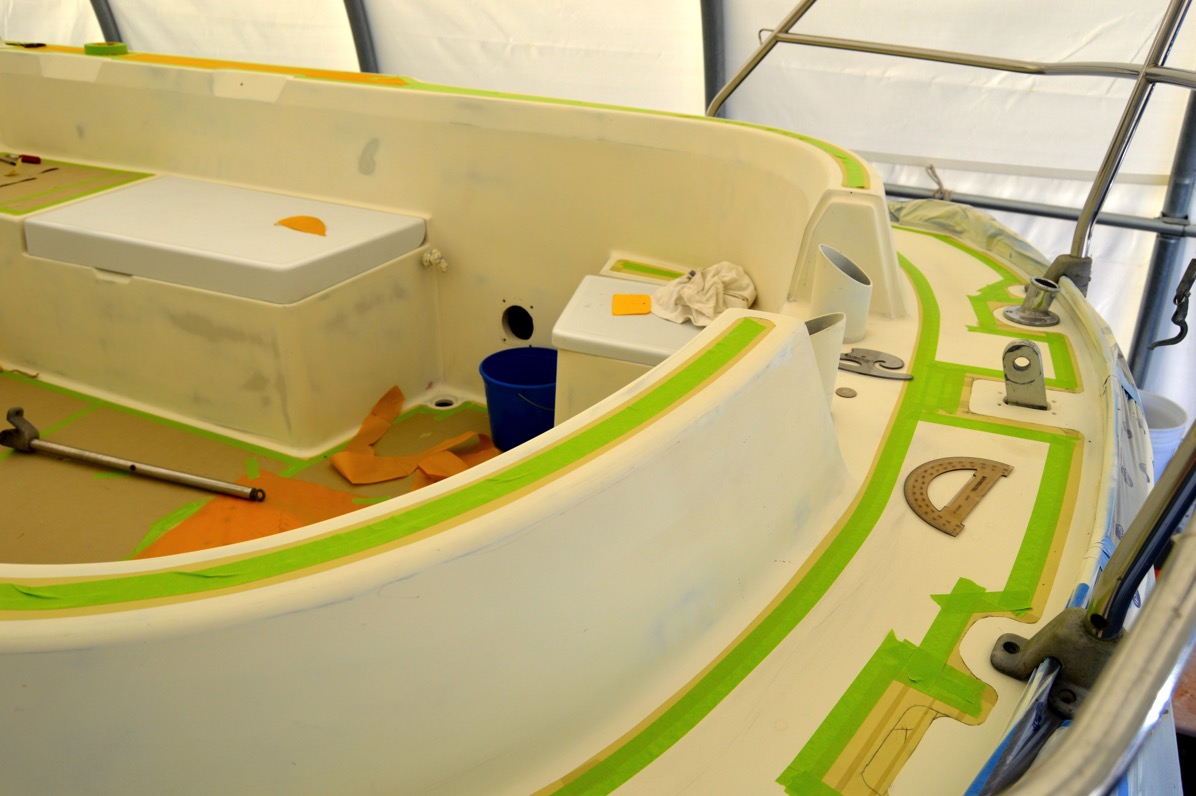

Now is the time to make things right. In addition to adding a new hot and cold cockpit shower to the system, I am replacing the faucets in the galley and the head. So rather than put a dirty sock on a clean foot, I decided to replace all the factory plumbing. This also aided with tying in my new hot-water tank.

I didn’t spend too much time evaluating material choices. I read of Onne van der Wal doing this on his Pearson 36 refit and the “PEX” solution seemed the easiest. I used 1/2” SeaTech polyethylene tubing and their line of connectors. I ordered them through the Paxton catalog that my yard uses and had them put the costs on my bill.

Being a noob to plumbing I will say that the job was pretty simple and straightforward. The revelation for me was the fact that the tubing is not terribly flexible. I was under the impression, delusion really, that the pipe could be contorted into all sorts of tight bends and angles. Not so. This required a bit more in the way of connectors, mostly elbows that I had not planned on when I drew up a schematic of the new system. Paxton and my yard were happy to remedy that shortcoming.

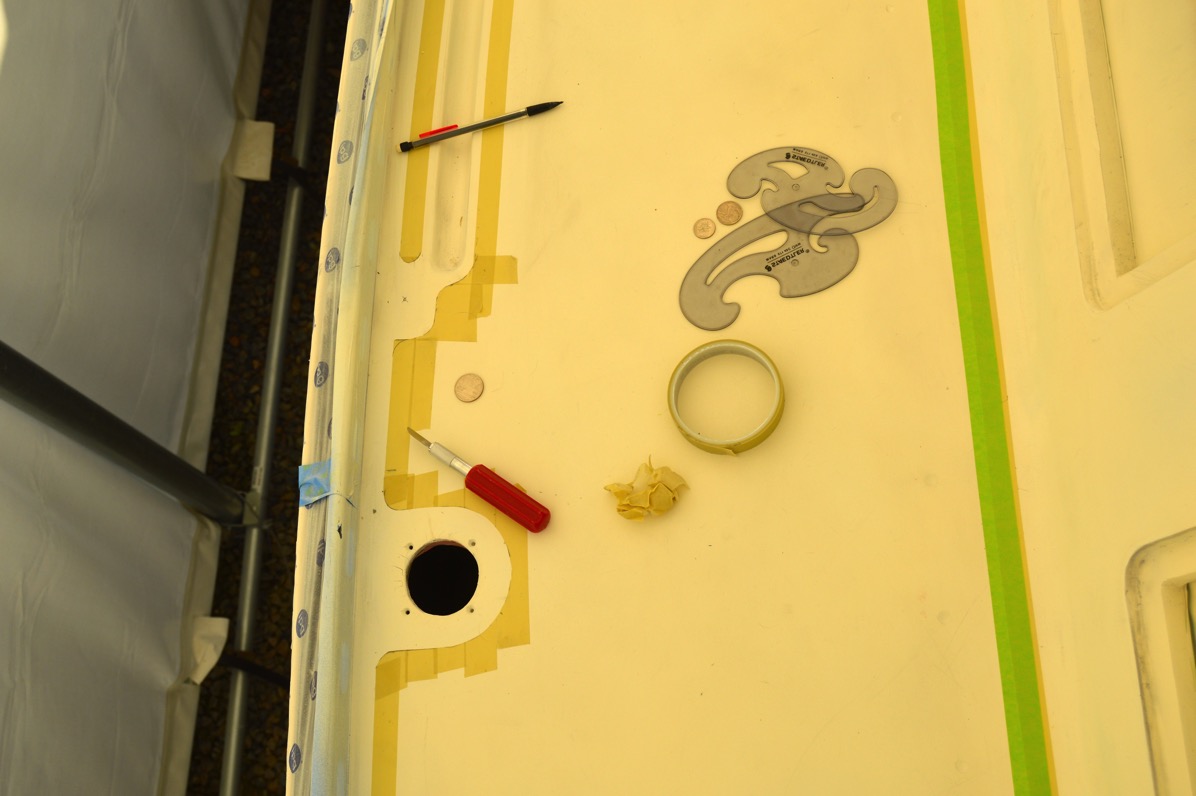

Pulling all the old tubing and running the new probably took about a day and a half. Not too much elbow grease necessary. Wherever possible I used insulated marine electrical cable clamps to secure the tubing and in some cases to shape the radius of a curve. Pro tip: buy the tube cutter.

One item that I envisioned doing was to create a manifold for the freshwater supply from the two 30-gallon tanks located under each main-cabin settee. C&C’s original approach was to add a valve to the supply line on each tank. When one went dry I pulled up the settee cushions and switched it closed and the other tank I put in open. Pretty simple. But in my usual “turn a sow’s ear into a silk purse” I figured I could combine those two valves into one and be done with it.

The more I thought about where to put the manifold and the extra time it would take I realized that it wasn’t worth it to me. I’m not going voyaging and we don’t use the boat enough to justify it. And I am waaaaay behind on this project.

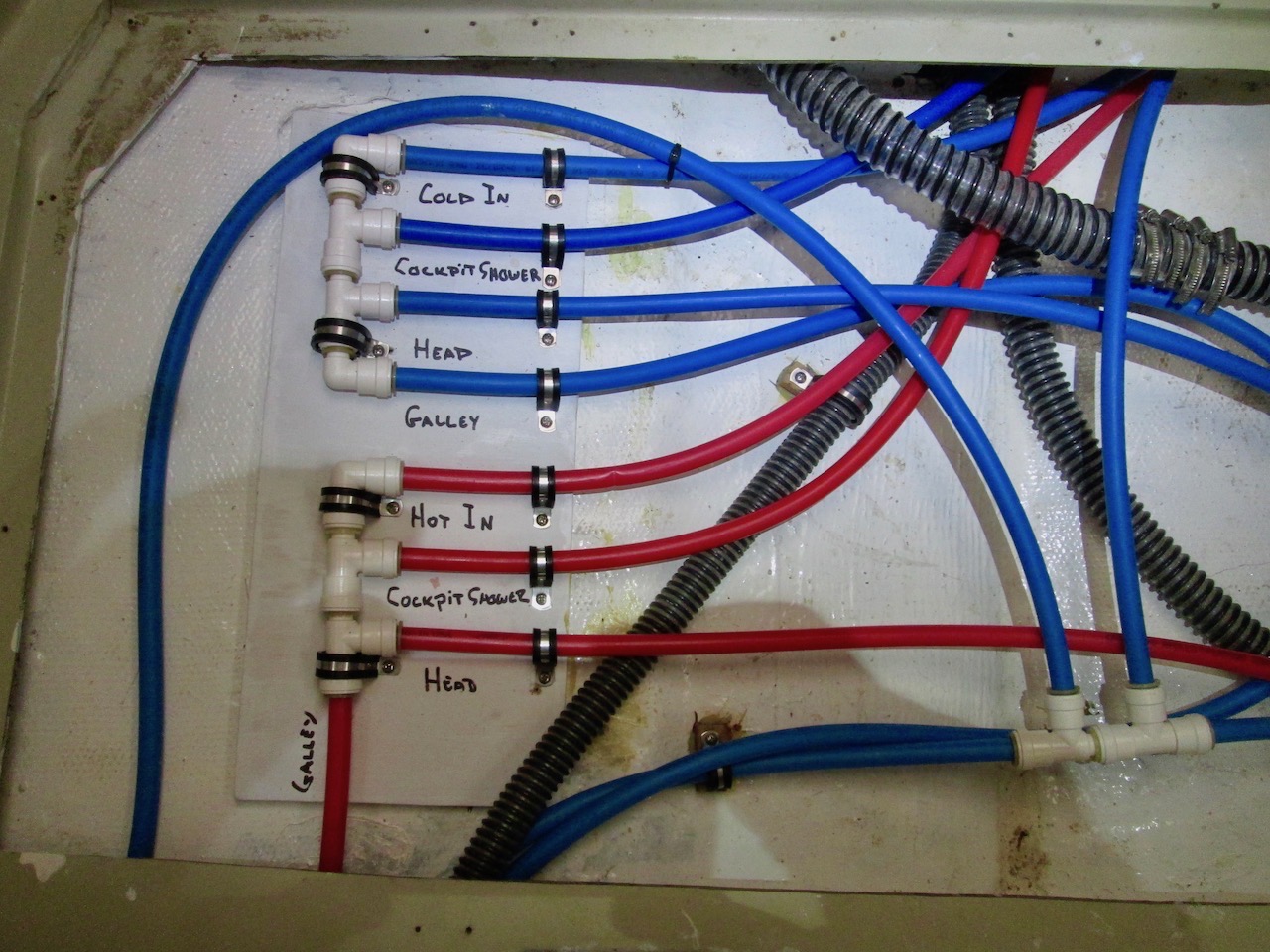

The only “manifold” that I did construct was for the high-pressure side that supplies hot and cold water. Because I was going from two to three high pressure supply lines, I constructed a manifold that distributed to each using stackable “T’s” and elbows. There was no need to incorporate any valves in these, especially since the whole structure would be under the floorboards.

One thing that I did do as sort of a lark was to incorporate valves into each fresh-water tank’s vent line. I’ve known of instances where saltwater intake in the tanks happened, generally on long legs at deep heel angles. We’ll see how that works in the real world of the Chesapeake Bay and coastal cruising. My money is on overkill...

Next up: installing the new faucets and shower.

Note: Red lines used for the F/W tank vents are due to me running out of blue...

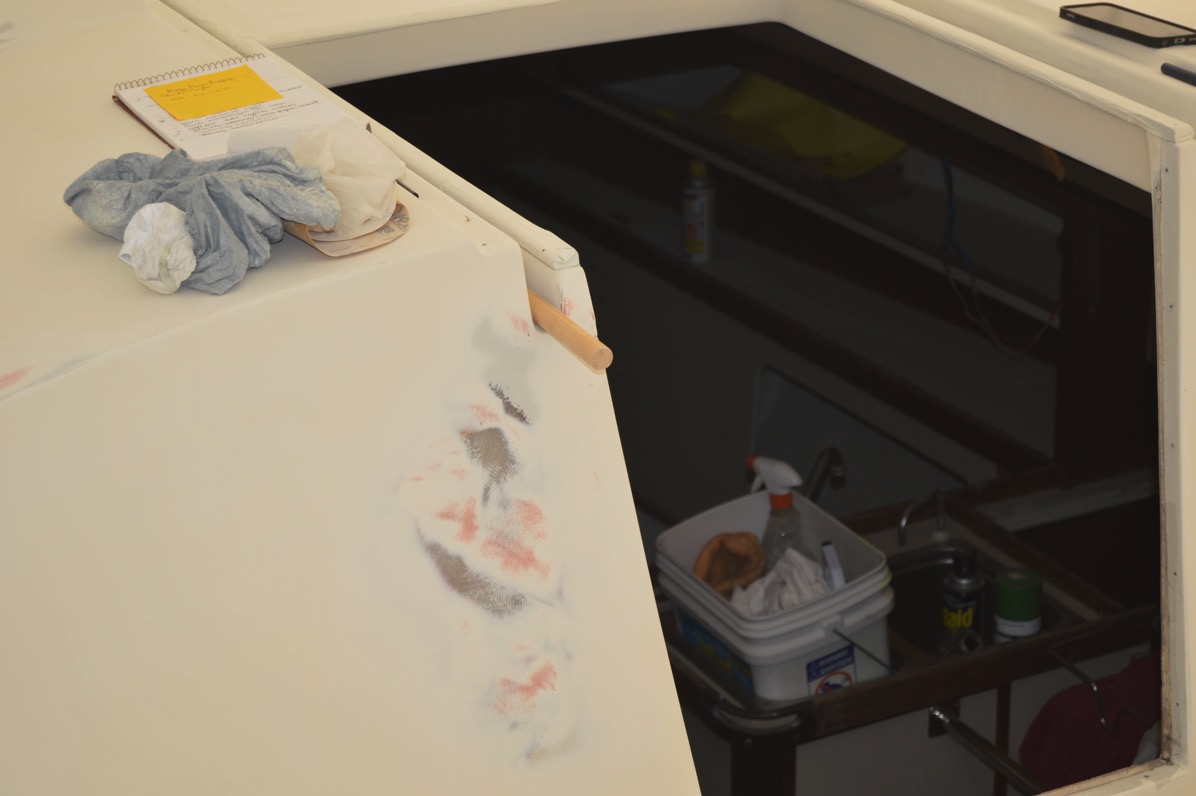

Yuck….

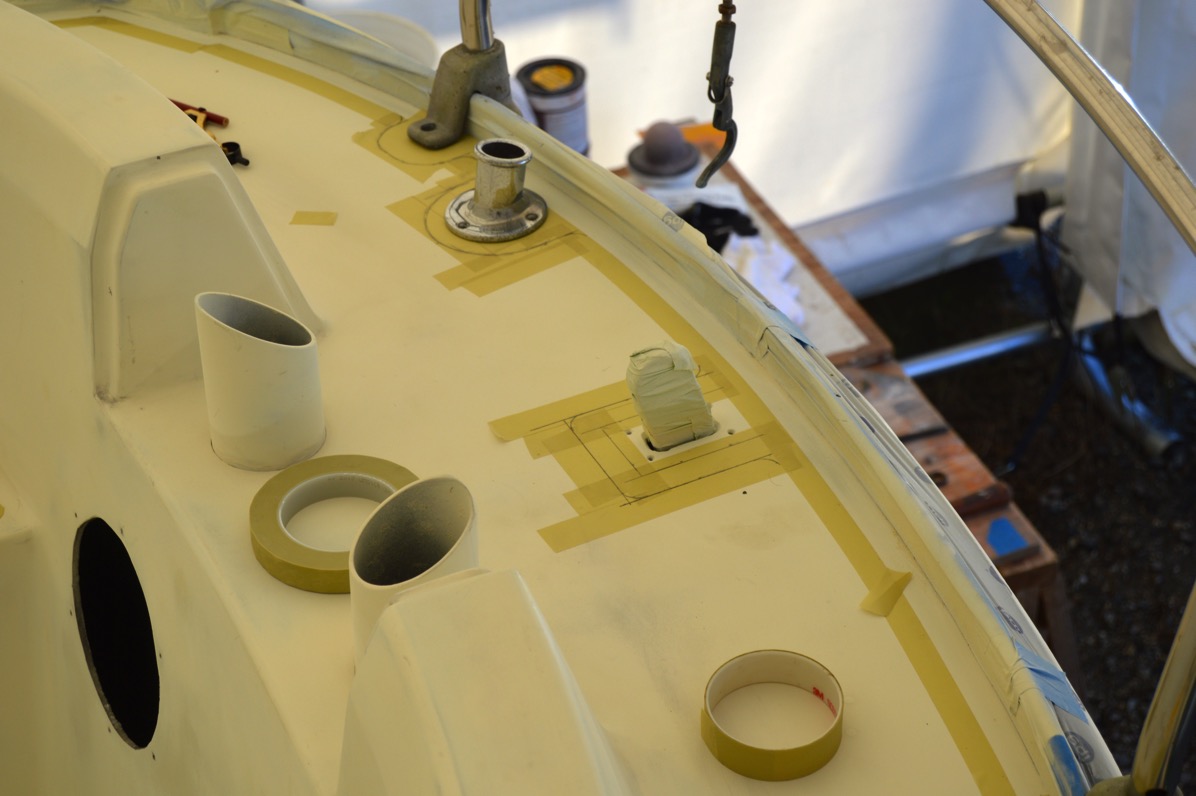

New filler hose with valve on vent line:

New filler hose with valve on vent line:

Starboard F/W tank hoses:

Shot showing the fresh-water pump, expansion tank and hot-water heater hookups:

Almost there:

And I will never see those line ID’s..